Creating a Kitchen Cabinet Cut List: Essential Elements for a Seamless Build

When it comes to cabinetry, precision is key. A well-cut and assembled cabinet is not only aesthetically pleasing but also functional and durable. To achieve this level of accuracy, a detailed cut list is essential. In this guide, we will delve into the crucial aspects of creating a kitchen cabinet cut list to ensure a successful project.

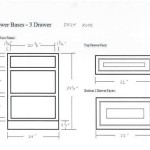

1. Gather Cabinet Plans and Specifications

The first step is to gather detailed cabinet plans, including elevations, plan views, and cross-sections. These plans should specify the overall dimensions, shelf heights, door openings, and hardware placement. Additionally, check any specific design features, such as crown molding or decorative elements.

2. Calculate Part Dimensions

Using the cabinet plans, begin calculating the dimensions for each individual cabinet part. Consider the materials you are using, such as plywood or MDF, and allow for proper clearances for doors, drawers, and hardware. Double-check all measurements to avoid costly errors.

3. Determine Grain Orientation

Pay attention to the grain orientation of the material you are using. For plywood, the grain should run parallel to the edges of the parts that will be visible, such as exposed sides and drawer fronts. This enhances both the strength and aesthetic appeal of the cabinet.

4. Label Parts Clearly

As you create the cut list, assign clear labels to each part. This will prevent confusion during the cutting and assembly process. Use descriptive labels that indicate the part's location and function, such as "Left Side Panel" or "Top Shelf." Consider using a different color or typeface for each part to make them easily identifiable on the cut sheet.

5. Specify Hardware and Accessories

Include all necessary hardware and accessories in the cut list. This includes hinges, drawer slides, handles, and any other components required for assembly. Specify the exact location of each hardware piece and the corresponding hole sizes for a precise installation.

6. Use Cut Optimization Software

To maximize material efficiency and minimize waste, consider using cut optimization software. This technology analyzes the cut list and finds the most efficient layout for cutting the parts from the available stock. It helps reduce material costs and ensures accurate cutting.

7. Review and Proofread

Before cutting any material, thoroughly review the cut list for accuracy. Check all dimensions, labels, and hardware specifications. Any errors at this stage can lead to costly mistakes or delays. If possible, have a second person proofread the list to minimize the risk of oversights.

Conclusion

A comprehensive and well-crafted kitchen cabinet cut list is the foundation for a successful project. By following these essential aspects, you can ensure precise cutting, efficient assembly, and a kitchen that meets your exact specifications. Remember to gather accurate plans, calculate part dimensions meticulously, pay attention to grain orientation, label parts clearly, specify hardware, utilize cut optimization software, and thoroughly review the cut list before cutting. With a well-executed cut list, you can create kitchen cabinets that are both beautiful and functional, adding value and enjoyment to your home.

Cutting List For Kitchen Cabinets Materials Sketchlist3d

Cutting List For Kitchen Cabinets Materials Sketchlist3d

Cabinet Pro Drawings And Cut List Reports

15in 4 Drawer Base Cabinet Carcass Frameless Rogue Engineer

600w Kitchen Base Cabinet Plans Cut List Renomart

30in Upper Cabinet Carcass Frameless Rogue Engineer

Cutting List Optimizer For Professional Works Wood Designer

Cutting List Kd Max 3d Kitchen Design South

Cutlist Plus Cutting Diagram Sheet Layout Optimizer For Plywood Panels And Lumber

Cabinet Cut List Spreadsheet Excelguider Com

Related Posts