Essential Aspects of CNC Kitchen Cabinet Files

CNC kitchen cabinet files are digital representations of the design and construction plans for kitchen cabinets. These files are essential for the efficient and accurate production of cabinets using computer-controlled (CNC) machinery. They provide precise instructions for the cutting, shaping, and assembly of cabinet components, ensuring that the finished products meet the desired specifications and quality standards.

Several key aspects influence the quality and functionality of CNC kitchen cabinet files. These include:

- File Format: The file format used to create the CNC files determines the compatibility with different software and machines. Common file formats include DXF, DWG, and G-code.

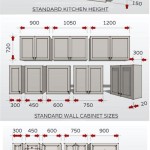

- Accuracy and Precision: The accuracy and precision of the files directly impact the quality of the finished cabinets. Accurate measurements and precise toolpaths ensure that the cabinets are cut and assembled to within specified tolerances.

- Toolpath Optimization: Efficient toolpaths minimize machine time and reduce material waste. Optimized toolpaths consider factors such as tool selection, cutting speed, and feed rate.

- Hardware Integration: The files should be compatible with the specific CNC machinery and tooling used in the production process. Seamless hardware integration ensures accurate execution of the design plans.

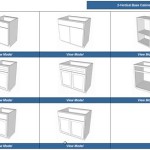

- 3D Modeling: 3D modeling software allows designers to create realistic virtual representations of the cabinets. This helps visualize the final product and identify potential design issues before production.

- File Management and Organization: Proper file management and organization are crucial for efficient workflow. Clearly labeled files and a structured folder system facilitate easy access and retrieval.

- Collaboration and Communication: CNC kitchen cabinet files facilitate collaboration between designers, engineers, and production teams. The files serve as a common reference point for ensuring that the final product meets the intended design specifications.

By understanding and optimizing these essential aspects of CNC kitchen cabinet files, manufacturers can achieve high-quality production, reduce errors, and improve efficiency. This ultimately results in superior finished products that meet the aesthetic and functional requirements of customers.

Cnc Cabinet Design To Turbocharge Ion

Simple Cabinet Plans With Cnc File Wilker Do S

Cnc Cabinet Design To Turbocharge Ion

38 Inch Kitchen Base Corner Cabinet Carcass Cnc File

Kitchen Cabinets Made By Cnc Router Projects

Cnc Kitchen Cabinets Legacy Woodworking Take A Test Drive

53 Cnc Kitchen Ideas Plywood Furniture

Kitchen Cabinet Washing Dishes Free Vector For Laser Cut Cnc Files

30 Inch Kitchen Upper Wall Cabinet Frame Carcass Cnc

Cnc Cabinet Design To Turbocharge Ion

Related Posts