CNC Router Kitchen Cabinets: A Comprehensive Guide

CNC router kitchen cabinets are a popular choice for homeowners and businesses alike. They offer a number of advantages over traditional methods of cabinet construction, including precision, consistency, and efficiency. In this article, we will explore the essential aspects of CNC router kitchen cabinets, including the benefits, types, and construction process.

Benefits of CNC Router Kitchen Cabinets

CNC router kitchen cabinets offer a number of benefits over traditional methods of cabinet construction, including:

- Precision: CNC routers are computer-controlled machines that can cut wood with extreme precision. This precision ensures that all of the pieces of a CNC router kitchen cabinet will fit together perfectly, resulting in a high-quality, finished product.

- Consistency: CNC routers can produce multiple copies of the same cabinet with identical precision. This consistency is ideal for large-scale projects or for businesses that need to produce a large number of cabinets.

- Efficiency: CNC routers can cut wood much faster than traditional methods of cabinet construction. This efficiency can save time and money on large projects.

Types of CNC Router Kitchen Cabinets

There are two main types of CNC router kitchen cabinets: framed and frameless.

- Framed cabinets have a frame around the front of the cabinet. The frame is typically made of wood and is attached to the sides and top of the cabinet. Framed cabinets are more traditional in style and are often used in kitchens with a classic or country look.

- Frameless cabinets do not have a frame around the front of the cabinet. Instead, the doors and drawers are attached directly to the sides of the cabinet. Frameless cabinets have a more modern look and are often used in kitchens with a contemporary or minimalist style.

Construction Process of CNC Router Kitchen Cabinets

The construction process of CNC router kitchen cabinets typically involves the following steps:

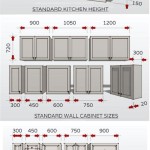

- Design: The first step is to design the cabinets. This can be done using a computer-aided design (CAD) program. The design should include the dimensions of the cabinets, the type of wood to be used, and the hardware to be installed.

- Cutting: Once the design is complete, the wood is cut to the specified dimensions using a CNC router. The CNC router is a computer-controlled machine that can cut wood with extreme precision.

- Assembly: The next step is to assemble the cabinets. This involves attaching the sides, top, and bottom of the cabinets together. The hardware is also installed at this stage.

- Finishing: The final step is to finish the cabinets. This may involve painting, staining, or applying a clear finish. The finish will protect the cabinets from moisture and wear and tear.

Conclusion

CNC router kitchen cabinets are a popular choice for homeowners and businesses alike. They offer a number of advantages over traditional methods of cabinet construction, including precision, consistency, and efficiency. When choosing CNC router kitchen cabinets, it is important to consider the type of cabinets you want (framed or frameless), the wood you want to use, and the hardware you want to install. With proper care and maintenance, CNC router kitchen cabinets can last for many years.

Cnc Routers For Cabinet Making Affordable Easy To Use

Cnc Router For Cabinet Making Maker Tekcel Machinery

Cabinets Furniture Sabre Cnc

Make Cabinet Doors With A Cnc Router 6 Steps Rosene Toronto

Cnc Routers For Cabinet Making Affordable Easy To Use

Top Cnc Cabinetry Bot Tools Efficient Ion

Kitchen Cabinets Made By Cnc Router Projects

Top Cnc Cabinetry Bot Tools Efficient Ion

Cnc Routers For Cabinet Making Affordable Easy To Use

How To Make Kitchen Cabinet Doors With Cnc Router Igolden