Custom Maple Cabinets: Understanding the Cost Per Square Foot

Maple is a favored hardwood for custom cabinetry due to its strength, durability, and attractive grain pattern. Its versatility allows it to be stained in a wide range of colors, making it suitable for diverse kitchen and bathroom designs. When planning a kitchen or bathroom remodel involving custom maple cabinets, understanding the cost per square foot is crucial for budgeting and making informed decisions.

The cost per square foot for custom maple cabinets is not a fixed figure. It's influenced by several factors, including the complexity of the design, the grade and quality of maple used, the hardware choices, and the labor rates in your geographical location. Therefore, obtaining accurate estimates from multiple cabinetmakers is essential for effective cost comparison and project planning.

Factors Influencing the Cost Per Square Foot

Several key components contribute to the overall cost per square foot of custom maple cabinets. Understanding these factors will help in navigating the pricing process and identifying areas where costs can potentially be adjusted.

1. Grade and Quality of Maple:

The grade of maple significantly impacts its price. Higher grades, such as Select and Better, exhibit fewer knots and imperfections, resulting in a cleaner, more uniform appearance. These grades are typically more expensive than lower grades like Common or Rustic, which may contain knots, mineral streaks, and color variations. The choice of maple grade depends on the desired aesthetic and budget constraints.

Kiln-drying processes also affect the quality and stability of the wood. Properly kiln-dried maple is less prone to warping, cracking, or shrinking over time, leading to a more durable and long-lasting cabinet. Cabinets crafted from improperly dried maple may exhibit structural issues, resulting in costly repairs or replacements. Therefore, verifying the kiln-drying process employed by the cabinetmaker is crucial for ensuring the longevity of the investment.

2. Design Complexity and Customization:

The complexity of the cabinet design directly impacts the labor hours required for fabrication and installation. Intricate details, such as raised panel doors, detailed moldings, custom carvings, and elaborate trim work, increase the time and skill needed to produce the cabinets, thus raising the cost per square foot. Simpler designs with slab doors, minimal ornamentation, and straightforward construction methods will generally be more cost-effective.

Customization also plays a significant role. Unique features like pull-out shelves, integrated appliance panels, specialized storage solutions, and custom dimensions require more detailed planning, fabrication, and fitting, all of which add to the overall expense. The degree of customization should be carefully considered in relation to the budget to ensure the project remains financially feasible.

3. Hardware and Accessories:

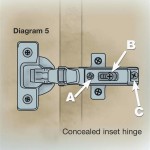

The choice of hardware, including hinges, drawer slides, knobs, and pulls, contributes to the overall cost. High-end hardware made from premium materials, such as solid brass or stainless steel, is significantly more expensive than standard hardware made from less durable materials. Soft-close hinges and drawer slides, which provide smoother and quieter operation, are also typically priced higher than traditional options.

Accessories, such as built-in organizers, spice racks, pull-out waste containers, and lighting systems, can further enhance the functionality and convenience of custom maple cabinets. However, these additions also add to the overall cost. Select accessories strategically to maximize utility and stay within the budget.

4. Finish and Staining:

The finish applied to the maple cabinets affects both its aesthetic appeal and its durability. Different finishing techniques, such as staining, painting, glazing, and distressing, impact the cost. Staining maple is a popular choice as it enhances the natural grain pattern of the wood. The complexity of the staining process, including the number of coats and the level of detail involved, influences the price.

Painting maple cabinets requires a meticulous preparation process, including sanding, priming, and applying multiple coats of paint. The cost of painting may also vary depending on the type of paint used and the number of layers required. Glazing and distressing techniques, which add depth and character to the cabinets, require specialized skills and time, adding to the cost. A durable, professional finish is crucial for protecting the maple from moisture, scratches, and other forms of wear and tear, so investing in a high-quality finish is a worthwhile consideration.

5. Installation Costs:

Installation costs account for a substantial portion of the overall project budget. The complexity of the installation process, the existing kitchen or bathroom layout, and the need for any modifications to plumbing or electrical systems will affect the labor costs. Experienced and skilled installers will typically charge higher rates due to their expertise and ability to ensure a precise and professional installation. Proper installation is essential to ensuring the longevity and functionality of the custom maple cabinets. It also prevents problems like uneven doors, misaligned drawers, and structural instability.

6. Geographical Location and Labor Rates:

Labor rates for cabinetmakers and installers vary significantly depending on the geographical location. Areas with higher costs of living typically have higher labor rates. Obtaining quotes from multiple local cabinetmakers allows for comparison shopping and ensuring a reasonable price for the project. Local demand for cabinetmakers also influences pricing. During peak construction seasons, demand may be higher, potentially leading to increased labor costs.

Estimating the Cost Per Square Foot

Estimating the cost per square foot for custom maple cabinets requires a detailed understanding of the scope of the project and the factors outlined above. A preliminary estimate can be obtained by considering the average range for custom maple cabinets, which typically falls between $300 and $1,200 per linear foot, or $75 to $350 per square foot. However, these figures are just estimates and can vary significantly based on the specific details of the project.

To obtain a more accurate estimate, it is crucial to consult with multiple cabinetmakers and provide them with detailed plans, specifications, and design preferences. A professional cabinetmaker will assess the project requirements, including the dimensions, design complexity, material choices, hardware selections, and finishing options, to provide a comprehensive and tailored quote. Requesting itemized quotes from each cabinetmaker will facilitate a detailed comparison of the costs associated with each aspect of the project. This transparency will allow for informed decisions and potential cost adjustments.

When reviewing the quotes, paying close attention to the fine print and clarifying any ambiguities is essential. Ensure that the quotes include all costs, such as materials, labor, installation, and any applicable taxes or fees. Consider the reputation and experience of the cabinetmaker as well. Reading online reviews, checking references, and reviewing past projects can provide valuable insights into the quality of their work and their customer service practices. Selecting a reputable and experienced cabinetmaker will help ensure a satisfactory outcome and a wise investment.

Strategies for Managing Cabinet Costs

Remodeling projects involving custom cabinets can be a considerable investment. Employing cost-saving strategies without compromising on quality or design is essential. Here are some strategies for managing custom cabinet costs effectively:

1. Simplify the Design:

Choosing simpler cabinet designs with fewer intricate details can significantly reduce labor costs. Opting for slab doors, minimal ornamentation, and straightforward construction methods can streamline the fabrication process and lower the overall price per square foot. While elaborate designs can be visually appealing, they require more time and expertise to create, adding to the expense. Consider a balance between aesthetic preferences and budget constraints by incorporating simpler designs in less visible areas, while reserving more elaborate details for focal points.

2. Choose Cost-Effective Materials:

While maple is a desirable wood for cabinetry, exploring alternative materials for certain components can help manage costs. Using maple for the doors and drawer fronts while utilizing a less expensive wood or plywood for the cabinet boxes can reduce the overall material costs without compromising the appearance. The interior of the cabinets is less visible, and using a more budget-friendly material in these areas is a viable cost-saving strategy.

3. Reface Existing Cabinets:

If the existing cabinet boxes are in good condition, refacing them instead of replacing them entirely can be a cost-effective alternative. Refacing involves replacing the doors, drawer fronts, and hardware to give the cabinets a fresh, new look. This option saves significant labor costs associated with demolition and installation of new cabinets. Refacing can provide a dramatic transformation without the expense of a complete cabinet replacement.

4. Consider Open Shelving:

Incorporating open shelving in strategic areas of the kitchen or bathroom can reduce the need for as many cabinets, thereby lowering the overall cost. Open shelves are typically less expensive than cabinets and can provide a stylish and functional storage solution. They are ideal for displaying frequently used items, decorative objects, and cookbooks, adding a touch of personality to the space. Consider a combination of open shelving and closed cabinets to balance aesthetics and storage needs.

5. DIY Partial Installation:

If you have the skills and experience, you can save on labor costs by handling some of the installation tasks yourself. Tasks such as demolition of the old cabinets, painting the walls, or installing the hardware can be done independently. However, it is essential to leave the more complex tasks, such as installing the cabinet boxes and ensuring proper alignment, to the professionals. This approach requires a realistic assessment of your skills and limitations to avoid potential mistakes that could lead to costly repairs.

6. Obtain Multiple Quotes and Negotiate:

Obtaining quotes from multiple cabinetmakers is crucial for comparing prices and finding the best value for your money. Requesting itemized quotes from each cabinetmaker will allow for a detailed comparison of the costs associated with each aspect of the project. Do not hesitate to negotiate with the cabinetmakers to see if they are willing to offer discounts or price matching. Being proactive and transparent about your budget can encourage them to find ways to reduce costs. It is important to communicate clearly about your expectations and budget constraints to ensure that both parties are on the same page.

Long-Term Value and Considerations

While the initial cost of custom maple cabinets may be higher than stock or semi-custom alternatives, they offer numerous long-term benefits that can justify the investment. Custom cabinets are designed and built to fit the specific dimensions and needs of the space, maximizing storage capacity and functionality. They are typically made from higher-quality materials and constructed with greater attention to detail, ensuring durability and longevity. Custom cabinets are also designed to reflect personal style and preferences, adding value to the home and enhancing its aesthetic appeal.

Maple cabinets are naturally durable and resistant to wear and tear, making them a wise investment for high-traffic areas like kitchens and bathrooms. A well-maintained set of custom maple cabinets can last for decades, potentially increasing the resale value of the home. The timeless appeal of maple ensures that the cabinets will remain stylish and relevant for years to come, even as design trends evolve. The ability to customize the cabinets to meet specific needs and preferences results in a more functional and enjoyable living space.

However, it’s imperative to remember that cost is a critical consideration when selecting custom maple cabinets. Thorough research, careful planning, and strategic implementation of cost-saving measures are necessary to ensure that the project remains within budget without compromising on quality and design.

Cost To Install Custom Cabinets Of Fixr

How Much Do Custom Cabinets Cost

How Much Does A Maple Shaker Style Cabinet Door Cost

Custom Kitchen Cabinets Cost Breakdown For 2025 Palm Beach Premier Remodeling

How Much Do Custom Cabinets Cost Authentic Cabinetry

Diamond Farrell 8 5 In W X 14 H Coastline Maple Stained Kitchen Cabinet Sample Printed Pfoamdr Farr Mp Ci At Com

Kitchen Cabinet S And Costs Explained

How Much Do Custom Cabinets Cost Breaking It Down

Custom Kitchen Cabinets Cost Breakdown For 2025 Palm Beach Premier Remodeling

Chestnut Maple Wood Cabinet Factory Kitchen Cabinets

Related Posts