How Are Kitchen Cupboards Attached to the Wall?

The secure and level installation of kitchen cupboards is crucial for both functionality and aesthetics. Improper installation can lead to sagging cabinets, misaligned doors, and even potential safety hazards. The process of attaching kitchen cupboards to the wall involves several key steps and relies on understanding wall construction, proper hardware selection, and precise execution. This article outlines the common methods and considerations involved in ensuring a stable and long-lasting kitchen cupboard installation.

Before any installation begins, a thorough assessment of the wall structure is essential. Determining the wall's composition – whether it is drywall over wood studs, plaster over lath, concrete, or brick – dictates the appropriate anchoring methods and hardware. Failing to account for the wall type can result in inadequate support and eventual failure of the installation.

Wood stud walls are the most common in residential construction and offer a relatively straightforward anchoring solution. These walls consist of vertical wooden studs, typically spaced 16 or 24 inches apart, covered with drywall. The studs provide a solid framework for attaching cabinets. However, locating these studs accurately is paramount. Stud finders, both magnetic and electronic, are commonly used to identify their position. Once located, the stud positions should be marked clearly along the wall to ensure precise screw placement during installation. In situations where studs are not conveniently located for cabinet placement, additional blocking may be required, which involves installing pieces of wood between the studs to provide a secure anchoring point.

Plaster walls over lath present a more challenging scenario. The lath, consisting of thin strips of wood, provides a weak substrate for screw attachment. Driving screws directly into the plaster and lath often results in crumbling and a loose connection. Special anchors, designed to expand within the wall cavity or grip the back of the plaster, are necessary. These anchors distribute the force over a wider area and prevent the fixture from pulling through the plaster. Toggle bolts, specifically, are a popular choice for plaster walls, as they provide a strong, secure hold.

Concrete or brick walls require specialized drilling and anchoring techniques. Standard wood screws are ineffective on these materials. Instead, masonry drill bits are used to create pilot holes for concrete or brick anchors. These anchors, such as wedge anchors or sleeve anchors, expand within the hole as the screw is tightened, creating a mechanical bond that resists pull-out forces. Selecting the correct type and size of anchor is critical, depending on the weight of the cabinets and the characteristics of the concrete or brick.

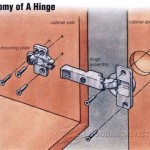

The type of cabinets being installed influences the mounting method. There are two broad categories: framed and frameless. Framed cabinets have a face frame around the cabinet box, providing a surface for attaching screws. Frameless cabinets, also known as European-style cabinets, lack this face frame and require different mounting techniques, often involving specialized mounting rails or plates.

1. Locating and Marking the Studs

The initial step in attaching kitchen cupboards to the wall, especially when dealing with wood-framed walls, is to precisely locate the studs. Using a stud finder, move slowly along the wall until the device indicates the presence of a stud. Mark the location with a pencil. Verify the location by driving a small finishing nail into the wall at the marked point. If the nail hits solid wood, the stud location is confirmed. If the nail encounters resistance but then pushes through, the stud finder might be indicating something else, such as a pipe or wire, or an inaccuracy. Repeat the process several times to establish the center of each stud. This center point is crucial for ensuring the screws are driven into the strongest part of the stud.

Once the studs are located, a horizontal line is drawn at the desired height for the base of the upper cabinets. This line serves as a reference point for installing a temporary support cleat, often made of a straight piece of lumber, which helps hold the cabinets in place during installation. A level is essential to ensure the line, and consequently the cabinets, are perfectly horizontal. The cleat is then screwed into the studs along the marked line. This cleat provides temporary support, freeing up both hands for leveling and securing the cabinets.

In situations where the wall is not perfectly level, shimming may be necessary. Shims are thin, tapered pieces of wood or plastic used to fill gaps and ensure the cabinets are aligned properly. They are typically placed behind the cabinet frame at the studs, compensating for any irregularities in the wall surface. Using a level placed on top of the cabinets ensures each cabinet is plumb and level before permanently attaching them.

2. Hardware Selection and Preparation

Selecting appropriate hardware is paramount for a secure and lasting cabinet installation. The length and type of screws are crucial considerations, dependent on the wall material and cabinet construction. For wood-framed walls, screws need to be long enough to penetrate the drywall and extend significantly into the wood stud, typically 2.5 to 3 inches. Cabinet mounting screws are specifically designed for this purpose, with a large, flat head that provides a secure grip on the cabinet frame.

For concrete or brick walls, specialized concrete screws or anchor bolts are required. These screws are typically hardened steel and feature threads designed to cut into the concrete or brick. The length of the screw depends on the thickness of the cabinet frame and the desired depth of penetration into the wall. Anchor bolts, used for heavier cabinets, provide an even more secure attachment. These bolts typically involve inserting an expanding sleeve into a pre-drilled hole, which then tightens around the bolt as it is inserted, creating a mechanical lock.

Before installing the cabinets, pre-drilling pilot holes is often recommended, especially when working with hardwood cabinets. Pilot holes prevent the wood from splitting when the screws are driven in, ensuring a cleaner and stronger connection. The size of the pilot hole should be slightly smaller than the diameter of the screw. This allows the screw threads to grip the wood securely without excessive force.

For frameless cabinets, specialized mounting hardware is often used. This hardware typically consists of metal rails that are attached to the wall and brackets that attach to the cabinet. The brackets then hook onto the rails, allowing for easy leveling and adjustment of the cabinets. The rails distribute the weight of the cabinets evenly along the wall, providing a more stable installation than direct screwing into the wall.

3. Installation Techniques and Best Practices

The actual installation process involves several key techniques to ensure a secure and aesthetically pleasing outcome. Begin by lifting the first cabinet onto the temporary support cleat. Ensure the cabinet is level and plumb, using shims as needed to compensate for any wall irregularities. Once the cabinet is positioned correctly, pre-drill pilot holes through the cabinet frame and into the wall studs. Drive the cabinet mounting screws through the pilot holes, tightening them securely but avoiding over-tightening, which can strip the screw threads or damage the cabinet frame.

When installing multiple cabinets, it is essential to clamp them together before screwing them to each other. Clamping ensures the cabinets are aligned perfectly and prevents gaps from forming between them. Use cabinet clamps, which feature soft pads to protect the cabinet surfaces, to secure the cabinets together. Drill pilot holes through the cabinet frames at the points where they meet, and then drive screws to join them together.

After all the cabinets are installed, inspect them carefully to ensure they are level, plumb, and properly aligned. Check the doors and drawers to ensure they open and close smoothly. Adjust the hinges and drawer slides as needed to achieve optimal performance. If any gaps are present between the cabinets and the wall, use caulk to seal them. Caulk not only improves the appearance of the installation but also prevents moisture from entering behind the cabinets, which can cause damage over time.

Consider the weight distribution within the cabinets when planning the installation. Heavier items should be stored in lower cabinets to minimize the risk of the upper cabinets pulling away from the wall. Reinforcing the wall with additional blocking or using heavier duty anchors can also provide added security for heavier cabinets.

Finally, always consult the manufacturer's installation instructions for specific recommendations regarding hardware, spacing, and other critical details. Adhering to these instructions ensures the cabinets are installed correctly and within the manufacturer's specifications, which can be important for warranty purposes.

Properly attaching kitchen cupboards to the wall involves a combination of careful planning, accurate execution, and the use of appropriate materials and techniques. By thoroughly assessing the wall structure, selecting the right hardware, and following best practices during installation, it is possible to achieve a secure, level, and aesthetically pleasing result that will enhance the functionality and appearance of the kitchen for years to come.

Wall Unit Fitting Adjustments Diy Kitchens Advice

How To Install Cabinets Like A Pro The Family Handyman

Installing Kitchen Cabinets Momplex Vanilla Ana White

How To Install Kitchen Cabinets The Wall And Floor With Ease

How To Install Kitchen Cabinets The Wall And Floor With Ease

How Are Kitchen Cabinets Attached To The Wall Ginger Brownies

How To Install Kitchen Cabinets The Wall And Floor With Ease

How Are Kitchen Cabinets Attached To The Wall

How To Fit Kitchen Units Checkatrade

Wall Unit Fitting Adjustments Diy Kitchens Advice

Related Posts