How Do You Install Scribe Molding On Kitchen Cabinets?

Scribe molding offers a polished, professional finish to kitchen cabinetry, seamlessly bridging the gap between cabinets and uneven walls. This specialized trim is custom-fit to the wall's contours, creating a flawless appearance. This article outlines the process of installing scribe molding, providing a detailed guide for achieving a professional result.

Before beginning the installation process, gather the necessary tools and materials. These include scribe molding stock (typically wood, MDF, or PVC), a coping saw, a pencil, a measuring tape, safety glasses, a miter saw (optional but recommended), wood glue, finishing nails, a nail set, and wood filler.

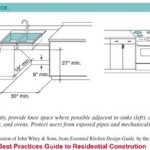

The first step involves accurate measurement. Measure the gap between the top of the cabinet and the wall at several points along the cabinet run. Variations in wall straightness necessitate multiple measurements to ensure the scribe molding accurately conforms to the wall's profile. Transfer these measurements onto the scribe molding stock. Mark the high points of the wall irregularities on the molding.

A compass can be a valuable tool for transferring complex curves from the wall to the molding. Set the compass width slightly wider than the largest gap between the cabinet and the wall. Run the compass along the wall, keeping one leg against the wall and the other tracing the contour onto the molding.

With the wall's profile traced onto the molding, the next step is cutting the molding to shape. A coping saw offers the best control for intricate cuts, allowing for precise shaping to match the wall's irregularities. Carefully follow the traced lines, cutting slightly outside the line to allow for minor adjustments. For longer, straight sections, a miter saw can be used for efficient cutting.

After cutting, test fit the scribe molding against the cabinet and wall. Minor discrepancies can be addressed with sandpaper or a file. The goal is a tight, gap-free fit against both the cabinet and the wall. This test-fitting stage is crucial for ensuring a professional finish.

Once a satisfactory fit is achieved, the molding is ready for installation. Apply a thin bead of wood glue to the back edge of the molding where it will contact the cabinet. This provides additional bonding strength. Position the molding against the cabinet, ensuring it aligns correctly with the wall's contours.

Secure the molding to the cabinet using finishing nails. Space the nails approximately every 12 to 16 inches. A nail set is used to countersink the nail heads slightly below the surface of the molding, preventing interference with the finishing process.

After securing the molding, fill the nail holes with wood filler. Allow the filler to dry completely according to the manufacturer's instructions. Once dry, lightly sand the filled areas smooth, ensuring they are flush with the surrounding molding surface. This creates a seamless, professional appearance.

The final step involves finishing the scribe molding to match the existing cabinetry. This might involve painting, staining, or applying a clear coat. Careful attention to detail during the finishing process ensures a cohesive and polished look. Multiple coats may be required to achieve the desired finish, allowing ample drying time between each coat.

Installing scribe molding requires precision and patience, but the resulting seamless transition between cabinets and walls elevates the overall aesthetic of the kitchen. Properly installed scribe molding provides a professional touch, concealing imperfections and enhancing the visual appeal of the cabinetry.

Different materials offer varying advantages and disadvantages. Wood provides a traditional look and can be easily stained to match existing cabinetry. MDF is a cost-effective option, offering a smooth surface for painting. PVC is moisture-resistant, making it suitable for areas prone to humidity, but it may not offer the same aesthetic appeal as wood or MDF.

When selecting scribe molding material, consider the existing cabinetry material and the overall style of the kitchen. Consistency in material and finish creates a cohesive and harmonious look. The chosen material should complement the existing design elements.

For complex wall profiles, consider creating templates from cardboard or thin plywood. These templates can be used to trace the wall's contours onto the molding material with greater accuracy. This technique is particularly helpful for walls with significant irregularities or intricate curves.

Safety is paramount throughout the installation process. Always wear safety glasses when cutting or sanding. Ensure the work area is well-ventilated when using adhesives or finishes. Follow manufacturer instructions for all materials and tools.

How To Patch Add Kitchen Cabinet Scribe Mold

What Is Scribe Molding Definition Of

Crown Installation On Kitchen Cabinets Issue Contractor Talk Professional Construction And Remodeling Forum

7 Types Of Cabinet Moldings And How To Use Them Properly

Scribing Part Two Making Cabinets Fit Seamlessly Into Irregular Surroundings Popular Woodworking

7 Types Of Cabinet Moldings And How To Use Them Properly

Kitchen Cabinet Trims Mog Bathroom Remodeling Marietta

Moldings Finish And Trim With Gary Striegler Part 14

10 Types Of Kitchen Cabinet Molding For Your Home

Kitchen Cabinet Trims Mog Bathroom Remodeling Marietta

Related Posts