How to Install Trim Around Kitchen Cabinets

Installing trim around kitchen cabinets can significantly enhance the visual appeal of a kitchen. Trim adds a finished, professional look while covering gaps and imperfections between cabinets and walls or ceilings. This article provides a detailed guide on how to successfully install trim around kitchen cabinets, covering preparation, material selection, installation techniques, and troubleshooting.

Before commencing the installation process, it is crucial to understand the different types of trim and their specific applications. Common types of trim used around kitchen cabinets include:

- Crown Molding: Placed at the top of cabinets, where they meet the ceiling, to create a decorative transition and conceal any unevenness.

- Light Rail Molding: Installed on the underside of wall cabinets to conceal under-cabinet lighting and provide a more finished appearance.

- Base Molding: Used at the bottom of base cabinets, where they meet the floor, to protect the cabinets from damage and hide gaps.

- Scribe Molding: A thin, flexible trim that is used to fill gaps between cabinets and walls, particularly useful when the walls are not perfectly straight.

- Filler Panels: Flat pieces of wood or MDF used to fill gaps between cabinets or between cabinets and walls, providing a seamless look before trim is applied.

Key Point 1: Preparation and Material Gathering

Proper preparation is paramount to a successful trim installation. This involves accurately measuring the areas where the trim will be installed, selecting the appropriate materials, and gathering the necessary tools. Neglecting this stage can lead to inaccurate cuts, mismatched trim, and a less-than-professional finished product.

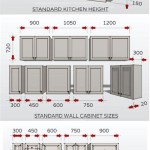

Accurate Measurement: Begin by meticulously measuring the length of each cabinet run where the trim will be applied. Be precise; even small discrepancies can become noticeable. For crown molding, measure not only the length but also the angles where the trim will meet at corners. Use a protractor or angle finder to determine the exact angles, especially if the corners are not perfectly square.

Material Selection: Choose trim materials that complement the existing cabinetry and kitchen décor. Wood trim, such as pine, oak, or maple, can be stained or painted to match the cabinets. MDF (Medium-Density Fiberboard) is another popular option, as it is less expensive than solid wood, easy to work with, and readily accepts paint. Ensure sufficient quantity of the chosen trim is purchased, accounting for waste from cuts and potential errors. It is advisable to purchase slightly more than the calculated amount to avoid running short.

Tool Acquisition: Gather all the necessary tools before starting the installation. Essential tools include:

- Miter Saw: For making precise angle cuts on trim, particularly crucial for crown molding.

- Measuring Tape: For accurate measurements of cabinet runs and trim pieces.

- Pencil: For marking cut lines on the trim.

- Level: To ensure the trim is installed straight and level.

- Stud Finder: To locate studs behind the drywall, which is necessary for securing the trim.

- Nail Gun: For attaching the trim to the cabinets or walls quickly and securely. A brad nailer is typically sufficient for most trim applications.

- Construction Adhesive: For added adhesion, especially when attaching trim to surfaces that are not easily nailed.

- Caulk and Caulk Gun: To fill any gaps between the trim and the cabinets or walls, creating a seamless finish. Choose a paintable caulk if the trim will be painted.

- Wood Filler: To fill any nail holes or imperfections in the trim before painting or staining.

- Sandpaper: To smooth out any rough edges or imperfections on the trim.

- Safety Glasses and Dust Mask: To protect eyes and lungs from sawdust and debris.

Key Point 2: Trim Cutting and Fitting

Cutting and fitting trim accurately is essential for achieving a professional-looking result. Incorrect cuts can lead to unsightly gaps and mismatched corners. This section details the techniques for cutting different types of trim and ensuring a tight, seamless fit.

Crown Molding Cutting Techniques: Crown molding presents a unique challenge due to its complex angles. Two primary methods exist for cutting crown molding:

- Flat Cutting: This method involves laying the crown molding flat on the miter saw bed and adjusting the miter and bevel angles to achieve the desired cut. This technique requires careful calculation of the angles based on the spring angle of the crown molding (the angle at which the crown molding sits against the wall and ceiling).

- Nested Cutting: This method involves placing the crown molding in the miter saw as it would sit against the wall and ceiling. Jigs or specialized crown molding stops are often used to hold the molding in the correct position. This method simplifies the angle calculations but requires more physical manipulation of the molding.

Regardless of the chosen method, always make test cuts on scrap pieces of trim to ensure the accuracy of the angles before cutting the final pieces. Remember to account for left and right corner cuts; they are mirror images of each other.

Scribe Cutting: When installing trim against a wall that is not perfectly straight, scribe cutting may be necessary. This technique involves tracing the contour of the wall onto the back of the trim and then carefully cutting along the traced line. To scribe cut, hold the trim against the wall and use a compass or dividers to transfer the wall's contour onto the trim. Set the point of the compass to the widest gap between the trim and the wall, and then run the pencil end of the compass along the wall while keeping the point against the trim. This will create a line on the trim that mirrors the wall's irregularities. Carefully cut along this line using a coping saw or a jigsaw.

Dry Fitting: Before permanently attaching any trim, dry fit each piece to ensure it fits properly. This involves holding the trim in place without any fasteners to check for gaps, misalignments, or other issues. If any adjustments are needed, make them before applying adhesive or nails. Dry fitting allows for corrections without damaging the trim or cabinets.

Key Point 3: Trim Installation and Finishing

Once the trim has been accurately cut and fitted, the next step is to install it securely and finish it to blend seamlessly with the surrounding cabinetry. This involves applying adhesive, using a nail gun, filling nail holes, and caulking any gaps.

Adhesive Application: Apply a bead of construction adhesive to the back of the trim before attaching it to the cabinets or walls. The adhesive provides additional holding power and helps to fill any minor gaps. Choose an adhesive that is specifically designed for trim and molding and that is compatible with the materials being used. Follow the manufacturer's instructions for application and curing time.

Nail Gun Attachment: Use a nail gun to secure the trim in place. Angle the nails slightly to increase their holding power. For crown molding, nail into the cabinet stiles and rails, as well as into the wall studs behind the drywall. Use a stud finder to locate the studs and mark their locations. For light rail molding, nail into the underside of the cabinet frames. For base molding, nail into the cabinet base and into the floor joists behind the baseboard. Be careful not to overdrive the nails, as this can damage the trim. Set the depth of the nail gun so that the nail heads are flush with the surface of the trim.

Filling Nail Holes and Gaps: After the trim has been installed, fill any nail holes and gaps with wood filler. Use a putty knife to apply the filler smoothly and evenly. Allow the filler to dry completely according to the manufacturer's instructions. Once the filler is dry, sand it smooth with fine-grit sandpaper. Be careful not to sand away the surrounding finish. After sanding, wipe away any dust with a damp cloth.

Caulking: Apply a bead of caulk along any gaps between the trim and the cabinets or walls. Use a caulk gun to apply the caulk evenly. Smooth the caulk bead with a wet finger or a caulk smoothing tool. Wipe away any excess caulk with a damp cloth. Choose a paintable caulk if the trim will be painted. Allow the caulk to dry completely before painting.

Painting or Staining: Once all of the nail holes and gaps have been filled and caulked, the trim is ready to be painted or stained. If painting, apply a primer coat first to ensure proper adhesion and coverage. Use a high-quality paint that is designed for trim and molding. Apply two coats of paint, allowing each coat to dry completely before applying the next. If staining, apply a wood conditioner first to ensure even stain absorption. Apply the stain with a brush or a rag, and wipe away any excess stain. Allow the stain to dry completely before applying a clear topcoat. Apply two coats of topcoat to protect the stain and provide a durable finish.

By following these steps carefully and meticulously, a homeowner can achieve a professional-looking trim installation that enhances the beauty and value of their kitchen.

Adding Molding To Cabinets Make Them Look Built In Young House Love

Adding Molding To Cabinets Make Them Look Built In Young House Love

How To Add Trim Cabinets

Moldings Finish And Trim With Gary Striegler Part 14

How To Add Molding Cabinets For A Gorgeous Finish Inspiration Moms

How To Add Molding Cabinets For A Gorgeous Finish Inspiration Moms

Adding Molding To Cabinets Make Them Look Built In Young House Love

The Easiest Way To Install Crown Molding On Cabinets

Adding Crown Molding To Cabinets Young House Love

Installing Crown Molding On Kitchen Cabinets