How To Make A Cut List For Cabinets

Creating a precise cut list is crucial for successful cabinet construction. A well-structured cut list minimizes material waste, reduces errors, and streamlines the assembly process. This document serves as a guide to generating a comprehensive cut list for cabinets, ensuring efficient project completion.

1. Gather Necessary Information

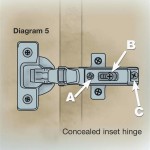

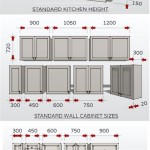

Before beginning the cut list, collect all relevant project details. This includes cabinet design plans, specifying dimensions for each cabinet component (e.g., face frames, side panels, shelves, doors, drawer fronts). Note the material thickness, which will influence final cut dimensions. Finally, determine the type of joinery to be used (e.g., butt joints, dadoes, rabbets). The joinery method impacts the required dimensions of various parts.

2. Create a Cabinet Component List

Develop a detailed list identifying every individual piece needed for each cabinet. This should include the component name (e.g., "Upper Cabinet Side Panel"), the quantity required, and a unique identifier for each part. For example, "UCS-1," "UCS-2" for two identical upper cabinet side panels. This organized approach helps track individual pieces throughout the construction process.

3. Calculate Finished Dimensions

Calculate the finished dimensions for each component based on the overall cabinet dimensions and the chosen joinery method. Account for the material thickness when determining final dimensions. For instance, if two panels connect with a butt joint, their combined width should equal the desired cabinet width. However, if using a dado joint, the width of the dado needs to be considered. Detailed drawings with accurate measurements are highly recommended during this stage.

4. Account for Material Thickness and Kerf

The kerf, the width of the saw blade's cut, must be factored into the final dimensions. Each cut removes a small amount of material. Failure to account for the kerf will result in parts slightly smaller than intended. Add the kerf width to the cut dimensions for each piece, ensuring accurate final dimensions.

5. Organize the Cut List

Structure the cut list in a clear, logical manner. Common methods include organizing by cabinet section (e.g., all upper cabinet components listed together), by material type (e.g., all plywood pieces listed together), or by cut size (e.g., all pieces requiring the same cut length grouped). Choose the organizational method that best suits the specific project and workflow.

6. Include Essential Information in the Cut List

A comprehensive cut list should include the following information for each component: the unique identifier, the component name, the material type, the finished dimensions (length, width, thickness), the quantity required, and any special notes regarding joinery or other specific instructions. This detailed information ensures clarity and minimizes errors during cutting and assembly.

7. Review and Double-Check

Before finalizing the cut list, thoroughly review all calculations and dimensions. Double-check the overall cabinet dimensions, individual component sizes, and the impact of joinery and kerf. Accurate measurements are critical to a successful project. A small error in the cut list can lead to significant problems during assembly. Careful review and verification can prevent costly mistakes and material waste.

Utilizing software designed for cabinet design can significantly simplify the process of generating cut lists. These programs automatically calculate dimensions and generate comprehensive cut lists, reducing the risk of errors and saving valuable time. Regardless of the method used, a meticulous approach to creating the cut list is essential for efficient and accurate cabinet construction.

Consider adding extra material to the cut list, especially for longer pieces prone to bowing or warping. This "overage" allows for trimming and ensures enough material for perfect final dimensions. Labeling each cut piece immediately after cutting can also be beneficial, preventing confusion and ensuring each component goes in its designated location during assembly.

Cutting List For Kitchen Cabinets Materials Sketchlist3d

Cutting List For Kitchen Cabinets Materials Sketchlist3d

15in 4 Drawer Base Cabinet Carcass Frameless Rogue Engineer

Cutlist Plus Cutting Diagram Sheet Layout Optimizer For Plywood Panels And Lumber

30in Upper Cabinet Carcass Frameless Rogue Engineer

Create A Cabinet Size Report Using Ecabinet Cut List In Excel Part 1

File Kitchen Cabienet Designs With Cut List Colab

Cutting List For Kitchen Cabinets Materials Sketchlist3d

The Best Sketchup Cutlist Plugin Opencutlist

Cutlist Plus Cutting Diagram Sheet Layout Optimizer For Plywood Panels And Lumber

Related Posts