Kitchen Appliance Garage Door Hardware: A Comprehensive Guide

The seamless integration of kitchen appliances into cabinetry is a hallmark of modern kitchen design. This streamlined aesthetic often involves concealing appliances behind cabinet doors, creating a clean and uncluttered appearance. A crucial element in achieving this look is the specialized hardware used to manage these doors, particularly when concealing larger appliances like refrigerators, dishwashers, or even pantry spaces. This specialized hardware, often referred to as "kitchen appliance garage door hardware" or "pocket door hardware," allows doors to retract neatly into the cabinetry, maximizing space and functionality.

This article explores the various types of kitchen appliance garage door hardware, their functional characteristics, installation considerations, and factors influencing their selection. It aims to provide a comprehensive understanding of this essential component in modern kitchen design.

Understanding the Mechanics of Appliance Garage Door Hardware

The defining characteristic of kitchen appliance garage door hardware is its ability to allow a cabinet door to completely disappear when open. Unlike traditional hinges that leave the door protruding into the kitchen space, these systems utilize a combination of hinges, slides, and tracks that guide the door smoothly inward and to the side, typically into a cavity or pocket within the cabinet structure. This mechanism frees up valuable floor space and improves the overall flow of the kitchen.

The core principle behind the functionality of this hardware lies in its ability to manage both the vertical and horizontal movement of the door. As the door is opened, it first pivots slightly inward, allowing it to clear the face of the cabinet. Simultaneously, the slides and tracks engage, guiding the door along a designated path into the recess. The complexity of this movement varies depending on the specific hardware system and the weight and size of the door.

The materials used in the construction of this hardware are crucial for its durability and smooth operation. High-quality steel, aluminum, and engineered plastics are commonly employed to ensure structural integrity and resistance to wear and tear. The finish of the hardware is also a consideration, often chosen to complement the overall aesthetic of the kitchen cabinetry.

Types of Kitchen Appliance Garage Door Hardware Systems

Several distinct types of kitchen appliance garage door hardware systems cater to different design requirements and appliance configurations. Each system offers a unique approach to retracting the door, influencing the installation process and the resulting aesthetics.

Pocket Door Slides: These systems typically involve a set of slides that are mounted to the cabinet frame and the door itself. As the door is opened, it slides horizontally into a pocket built into the cabinet. Pocket door slides are a common choice for hiding smaller appliances or creating concealed pantry spaces. The weight capacity of the slides is a critical factor to consider, ensuring they can handle the door's weight without compromising smooth operation.

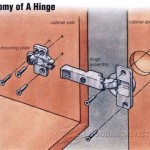

Bifold Doors with Concealed Hinges: In this configuration, the door is divided into two panels that fold together as they are pushed into the cabinet recess. Specialized concealed hinges allow the panels to fold smoothly and maintain a flush appearance when closed. Bifold systems are well-suited for wider openings, such as those concealing refrigerators or larger pantry storage areas. The quality of the hinges is paramount, as they bear the brunt of the stress during operation. The alignment and precise installation are essential for smooth operation and preventing binding.

Pivot and Slide Systems: These systems combine a pivoting motion with a sliding action. As the door is opened, it first pivots slightly inward, then slides horizontally into the cabinet. This configuration is particularly useful for concealing appliances that are set back from the cabinet face. The pivot mechanism ensures that the door clears the appliance without obstruction. Accurate measurements and precise installation are critical for optimal performance.

Lift-Up Systems: While less common for concealing entire appliances, lift-up mechanisms can be used for concealing smaller items or creating access to specific sections of a cabinet. These systems use gas springs or other lifting mechanisms to raise the door vertically, revealing the appliance or storage area. Lift-up systems are frequently used for concealing coffee makers or small appliances on countertops.

Key Considerations for Selecting the Right Hardware

Choosing the appropriate kitchen appliance garage door hardware involves careful consideration of several factors. The size and weight of the appliance being concealed, the available space within the cabinetry, and the desired aesthetic all play a role in the selection process.

Appliance Dimensions and Weight: The most crucial factor is the size and weight of the appliance that the door will conceal. The hardware must be rated to handle the door's weight without compromising its smooth operation or structural integrity. Overloading the hardware can lead to premature wear, binding, and even failure. Consult the hardware manufacturer's specifications to ensure that the chosen system is appropriate for the intended application. Measurements should be carefully taken and verified to ensure compatibility.

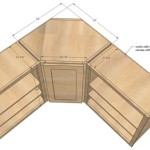

Cabinetry Design and Space Availability: The design of the cabinetry and the available space within the cabinet are also critical considerations. The hardware requires sufficient space to operate smoothly, and the pocket or recess for the door must be adequately sized. Consider the depth of the appliance and the amount of space needed for the door to retract completely. In some cases, modifications to the cabinet structure may be necessary to accommodate the hardware. Pre-planning the cabinet design with the hardware in mind is crucial for seamless integration.

Aesthetic Considerations: The aesthetic of the kitchen is also an important factor. The hardware should be chosen to complement the overall design of the cabinetry. Consider the finish of the hardware and its visibility when the door is open or closed. Concealed hinges and flush-mounted slides can help to maintain a clean and uncluttered appearance. The door material and design should also blend seamlessly with the surrounding cabinetry to create a cohesive look.

Installation Complexity and Expertise: The complexity of the installation process should not be overlooked. Some hardware systems are relatively straightforward to install, while others require specialized tools and expertise. Consider your own level of skill and experience before attempting to install the hardware yourself. If unsure, it is always best to consult with a professional cabinet maker or installer.

Durability and Longevity: The durability and longevity of the hardware are essential for ensuring its long-term performance. Choose hardware made from high-quality materials and designed to withstand the rigors of daily use. Look for hardware with a proven track record of reliability. Reviewing customer feedback and professional reviews can provide valuable insights into the hardware's performance and durability.

Budget Considerations: The cost of the hardware can vary significantly depending on the type, quality, and features. Establish a budget before beginning the selection process and compare prices from different suppliers. Keep in mind that investing in high-quality hardware can save money in the long run by reducing the need for repairs or replacements.

Installation Best Practices

Proper installation is crucial for the smooth and reliable operation of kitchen appliance garage door hardware. Incorrect installation can lead to binding, misalignment, and premature wear. Adhering to the manufacturer's instructions and employing best practices are essential for achieving optimal results.

Thoroughly Review Manufacturer Instructions: Always begin by carefully reviewing the manufacturer's instructions. These instructions provide detailed guidance on the installation process, including specific measurements, mounting locations, and adjustment procedures. Following these instructions precisely is essential for ensuring proper operation and avoiding potential problems. Do not assume that you know how to install the hardware based on previous experience; each system may have unique requirements.

Accurate Measurements and Marking: Precise measurements and accurate marking are critical for ensuring that the hardware is installed correctly. Use a high-quality measuring tape and level to ensure that all measurements are accurate and consistent. Mark the mounting locations carefully using a pencil or marking tool. Double-check all measurements before drilling any holes or attaching any components. Accuracy is paramount for preventing misalignment and ensuring smooth operation.

Proper Tool Selection: Use the appropriate tools for the job. This may include a drill, screwdriver, level, measuring tape, and other specialized tools as required by the manufacturer's instructions. Using the wrong tools can damage the hardware or the cabinet structure. Ensure that the drill bits and screwdriver bits are the correct size and type for the screws and fasteners being used. Investing in high-quality tools can make the installation process easier and more efficient.

Secure Mounting and Fastening: Ensure that all components are securely mounted and fastened. Use the appropriate screws and fasteners for the type of material being used. Over-tightening screws can damage the hardware or strip the threads, while under-tightening can lead to loose components and instability. Follow the manufacturer's recommendations for torque specifications. Using pilot holes can prevent splitting or cracking of the wood.

Testing and Adjustment: After installation, test the operation of the hardware thoroughly. Open and close the door several times to ensure that it moves smoothly and without binding. Adjust the hardware as needed to achieve optimal performance. Most systems have adjustment screws or mechanisms that allow for fine-tuning. Refer to the manufacturer's instructions for guidance on adjustment procedures.

Lubrication: Apply lubricant to the moving parts of the hardware to ensure smooth operation and prevent wear. Use a lubricant specifically designed for this purpose, such as a silicone-based spray or grease. Follow the manufacturer's recommendations for lubrication frequency and type.

Professional Consultation: If you are unsure about any aspect of the installation process, consult with a professional cabinet maker or installer. They have the expertise and experience to ensure that the hardware is installed correctly and safely. A professional installation can save time, prevent costly mistakes, and ensure optimal performance.

By understanding the mechanics, types, and considerations involved in selecting and installing kitchen appliance garage door hardware, homeowners and designers can create kitchens that are both functional and aesthetically pleasing. This hardware is a vital component of modern kitchen design, contributing to a seamless and uncluttered appearance.

Kitchen Appliance Garage Diy Angela Marie Made

13 Appliance Garage Ideas For A Clutter Free Kitchen Bob Vila

Medallion Cabinetry Appliance Garage With Easy Lift Up Door

Straight Appliance Garage Richelieu Hardware

Kitchen Design Idea Your Appliances In An Appliance Garage

Build A Diy Appliance Garage Basic

The Modern Day Appliance Garage A Moveable Backsplash To Hide Our Small Appliances Chris Loves Julia

How To Diy A Kitchen Appliance Garage Semistories

What Is An Appliance Garage Storage Ideas

Appliance Garage Kit Milano In The Häfele America

Related Posts