Essential Aspects of Kitchen Cabinet Box Construction

Kitchen cabinets play a crucial role in both the functionality and aesthetic appeal of a kitchen. The box construction of these cabinets, which forms the framework for the cabinetry, is of utmost importance in ensuring their durability, stability, and overall performance. Understanding the essential aspects of kitchen cabinet box construction will empower homeowners and professionals to make informed decisions when selecting and installing cabinets.

Materials

The choice of materials used in cabinet box construction directly influences its strength, longevity, and resistance to moisture and wear. The most commonly used materials for cabinet boxes include:

- Plywood: Composed of multiple layers of wood veneer glued together, plywood offers exceptional strength and stability. It is resistant to warping and buckling, making it a suitable choice for areas prone to moisture.

- Particleboard: A man-made material made from wood particles bonded together with resin, particleboard is an economical option that provides adequate strength for general use.

- Medium-density fiberboard (MDF): Similar to particleboard, MDF is composed of wood fibers but is denser and more uniform. It has smooth surfaces that are ideal for painting or laminating.

Construction Methods

The construction method used to assemble the cabinet box also impacts its strength and durability. The primary methods include:

- Staple and glue: The simplest and most economical method, where the cabinet components are held together using staples and glue.

- Dado and dowel: A stronger and more durable method, where grooves (dados) are cut into the cabinet sides and shelves, and wooden dowels are inserted for added stability.

- European-style frameless: A modern approach where the cabinet sides and shelves are joined using concealed connectors, resulting in a sleek and contemporary look.

Hardware

The hardware used in cabinet box construction, such as screws, nails, and hinges, plays a vital role in ensuring the cabinet's stability and longevity. It is recommended to use high-quality hardware that is appropriate for the specific materials and construction methods employed.

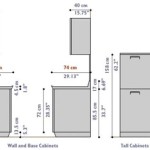

Cabinet Thickness

The thickness of the cabinet box sides and shelves affects the overall strength and durability of the cabinet. Thicker materials will provide greater support and resistance to bending and warping. Common thicknesses for cabinet boxes range from 1/2 inch to 1 inch.

Back Panel

The back panel, which is installed at the rear of the cabinet box, adds rigidity and stability to the overall structure. It also helps to prevent dust and debris from entering the cabinet. The back panel can be made from a variety of materials, including plywood, hardboard, or melamine.

Conclusión

Understanding the essential aspects of kitchen cabinet box construction empowers individuals to make informed decisions when selecting and installing cabinets. By considering the materials, construction methods, hardware, cabinet thickness, and back panel, homeowners and professionals can ensure that the cabinetry meets their specific functional and aesthetic requirements while providing long-lasting durability and performance.

Kitchen Base Cabinets 101 Ana White

How To Build Cabinets The Complete Guide Houseful Of Handmade

How To Build Cabinets The Complete Guide Houseful Of Handmade

Guide Kitchen Cabinetry Terms Builders Surplus

The Abcs Of Kitchen Cabinets Part 2 Akg Design Studio

Cabinet Composition What Makes A High Quality

How To Build Base Cabinets The Complete Guide Houseful Of Handmade

How To Build A Next Level Cabinet Box Revealed

Diy Kitchen Cabinets Made From Only Plywood

Cabinet Construction Framed Vs Full Access Linn S Prestige Kitchens And Bath

Related Posts