Kitchen Cabinet Carcasses Suppliers: A Comprehensive Guide

The kitchen cabinet carcass forms the structural foundation of any kitchen cabinetry system. Selecting the right supplier for these crucial components is paramount to the overall longevity, functionality, and aesthetic appeal of a kitchen design. This article provides a comprehensive overview of factors to consider when choosing kitchen cabinet carcass suppliers, highlighting key aspects of material quality, manufacturing standards, customization options, and supply chain reliability.

Material Selection and its Impact on Carcass Quality

The choice of material significantly influences the durability, stability, and water resistance of kitchen cabinet carcasses. Several materials are commonly employed, each possessing distinct advantages and disadvantages. Understanding these properties is vital for informed decision-making.

Particleboard is a widely used and cost-effective material. It is manufactured by compressing wood particles with resin and heat. While budget-friendly, particleboard is susceptible to moisture damage and may not be suitable for areas prone to spills or humidity. Its density can vary, impacting its screw-holding capabilities and overall structural integrity. Suppliers should provide detailed specifications regarding the particleboard’s density and the type of resin used.

Medium-Density Fiberboard (MDF) is another popular choice, offering a smoother surface and greater stability than particleboard. MDF is less prone to warping and is easier to paint or veneer. However, like particleboard, MDF is vulnerable to moisture damage if not properly sealed. Suppliers should specify the moisture-resistant qualities of the MDF if it is intended for use in damp environments. Its consistent density makes it ideal for complex milling and shaping.

Plywood is a stronger and more water-resistant option compared to particleboard and MDF. It is constructed from layers of wood veneer glued together, providing excellent dimensional stability and resistance to warping. Plywood is more expensive than the other two options but offers superior durability and longevity. Suppliers should provide information regarding the plywood’s grade (e.g., A, B, C, D) and core construction (e.g., veneer core, lumber core) to ensure the quality meets the required standards.

Solid wood is the most premium option, offering exceptional durability and natural aesthetic appeal. Solid wood carcasses are resistant to moisture and can withstand heavy loads. However, solid wood is also the most expensive option and is prone to expansion and contraction due to changes in humidity. Suppliers should specify the type of wood used (e.g., maple, oak, birch) and its moisture content to minimize the risk of warping or cracking. Solid wood carcasses often require specialized joinery techniques for optimal stability.

Beyond the core material, the edge banding used on carcasses plays a crucial role in moisture protection and aesthetics. Suppliers should offer a range of edge banding materials, including PVC, ABS, and wood veneer, ensuring a seamless and durable finish. The quality of the adhesive used for edge banding is also critical to prevent delamination over time.

Manufacturing Standards and Quality Control

The manufacturing processes employed by kitchen cabinet carcass suppliers directly impact the precision, consistency, and structural soundness of the finished product. Rigorous quality control measures are essential to ensure that carcasses meet specified dimensions and performance standards.

Automated manufacturing processes, such as CNC (Computer Numerical Control) machining, offer superior precision and consistency compared to manual methods. CNC machines can accurately cut, drill, and shape carcass components, minimizing the risk of errors and ensuring tight tolerances. Suppliers who invest in advanced manufacturing technology are more likely to deliver high-quality carcasses that meet stringent specifications.

Edge banding application is another critical aspect of carcass manufacturing. Automated edge banding machines ensure consistent adhesion and a seamless finish. Suppliers should utilize high-quality adhesives and edge banding materials to prevent delamination and moisture penetration. A well-applied edge band enhances the durability and aesthetic appeal of the carcass.

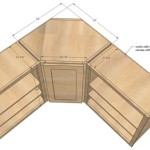

Joint construction is paramount to the structural integrity of the carcass. Common joint types include dowel joints, dado joints, and butt joints. Dowel joints provide added strength and stability, while dado joints create a strong and precise connection between components. Suppliers should utilize appropriate joint types based on the material and intended load-bearing capacity of the carcass.

Quality control procedures should be implemented throughout the manufacturing process. This includes regular inspections of raw materials, dimensional checks of cut components, and visual inspections of finished carcasses. Suppliers should maintain records of quality control checks to demonstrate their commitment to quality assurance. Utilizing industry standards such as the Kitchen Cabinet Manufacturers Association (KCMA) certification provides assurance of quality performance.

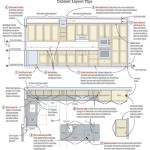

Suppliers should also provide clear documentation regarding the assembly instructions for their carcasses. This documentation should include detailed diagrams and step-by-step instructions to ensure proper installation. Providing pre-drilled holes and hardware simplifies the assembly process and minimizes the risk of errors.

Customization Options and Supply Chain Considerations

The ability to customize kitchen cabinet carcasses to specific design requirements is a significant advantage. Suppliers offering a wide range of customization options allow for greater flexibility and design freedom. Effective supply chain management is equally important to ensure timely delivery and minimize lead times.

Carcass dimensions, including width, height, and depth, should be customizable to accommodate various kitchen layouts and appliance sizes. Suppliers should offer a range of standard sizes and the option to create custom dimensions to meet specific needs. The ability to modify carcass dimensions allows for optimal space utilization and design flexibility.

Shelf placement and adjustability are crucial for maximizing storage capacity and functionality. Suppliers should offer adjustable shelf options, allowing users to customize the interior configuration of their cabinets. Pre-drilled holes or shelf support systems should be provided to facilitate easy shelf adjustment.

Door and drawer front options should be compatible with the carcasses. Suppliers should offer a variety of door and drawer front styles, materials, and finishes to match the overall kitchen design. Compatibility between carcasses and door/drawer fronts is essential for a cohesive and aesthetically pleasing result.

Lead times and shipping costs are important considerations when selecting a supplier. Suppliers should provide clear estimates of lead times and shipping costs upfront. A reliable supply chain is crucial for ensuring timely delivery and minimizing delays. Suppliers should have established relationships with reputable shipping companies and efficient logistics systems in place.

Warranty and support services are essential for protecting against defects and ensuring customer satisfaction. Suppliers should offer a reasonable warranty period against manufacturing defects and provide prompt and responsive customer support. Clear communication and efficient problem-solving are essential for building strong relationships with customers.

The location of the supplier can significantly impact shipping costs and lead times. Local suppliers may offer faster delivery and lower shipping costs compared to suppliers located further away. However, it is important to consider the supplier's overall capabilities and reputation, regardless of their location.

Beyond these considerations, the environmental impact of the carcasses should also be considered. Suppliers offering products made from sustainably sourced materials and utilizing environmentally friendly manufacturing processes are increasingly valued. This includes using Forest Stewardship Council (FSC) certified wood and minimizing waste during production.

Finally, assess the supplier's financial stability. A financially sound supplier is more likely to be able to fulfill orders reliably and honor warranty claims. Consider requesting financial statements or checking their credit rating before committing to a large order.

Modular Kitchen Carcass

Stainless Steel Kitchen Carcass

Kitchen Cabinet Carcasses At Best In Lucknow Uttar Pradesh Enox Modular Furniture

Kitchen Carcass At Best In Lucknow Uttar Pradesh Enox Modular Furniture

Kitchen Carcass And Cabinets

Standard Stainless Steel Cabinet Carcass At Best In Shatin Ming Tat Hong Group Hardware Supplier Co Ltd

Pvc Carcass Material Straight Modular Kitchen Cabinets

Modular Kitchen Carcass At Best In Lucknow Uttar Pradesh Enox Furniture

Modular Kitchen Carcass

Carcass Plywood Mdf Particle Board Modular Kitchen Cabinet Designs For Project China Cabinets Pet Made In Com

Related Posts