Kitchen Cabinet Manufacturing Jobs: A Detailed Overview

The kitchen cabinet manufacturing industry is a significant contributor to the overall home improvement and construction sectors. It encompasses the design, fabrication, assembly, and finishing of cabinets intended for kitchen and other residential spaces. This industry sustains a diverse workforce, offering a range of employment opportunities from entry-level positions to highly skilled technical roles. Understanding the various jobs available within this sector, the required skills, and the industry dynamics is crucial for individuals seeking employment or for businesses aiming to optimize their recruitment strategies.

The production of kitchen cabinets is a multi-stage process. It typically begins with the selection and preparation of raw materials, primarily wood, wood composites (like plywood and MDF), and hardware. Following material processing, components are manufactured to precise specifications. The assembly stage involves combining these components to form cabinet boxes, doors, and drawers. Finally, cabinets undergo finishing processes, including sanding, staining, painting, and applying protective coatings. Each stage demands specialized skills and contributes to the final quality and aesthetic appeal of the finished product.

The demand for kitchen cabinet manufacturing jobs is often influenced by economic factors such as housing market trends, consumer spending habits, and renovation rates. Periods of economic expansion typically witness increased construction activity and home renovation projects, leading to greater demand for kitchen cabinets and, consequently, more job opportunities. Conversely, economic downturns may lead to reduced demand, affecting employment levels within the industry. Technological advancements, such as the integration of CNC machinery and automated processes, also play a role in shaping the skills required of the workforce.

Understanding the Range of Job Roles

The spectrum of job roles within kitchen cabinet manufacturing is broad, catering to diverse skill sets and experience levels. These roles can be broadly categorized into production, design, sales & marketing, and management & administration. Within production, several specialized roles contribute to the efficient manufacturing of cabinets. Here's a closer look at some key positions:

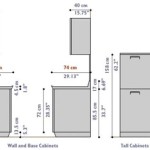

Cabinet Makers: Cabinet makers are responsible for the precise cutting, shaping, and assembly of cabinet components. They must be proficient in using a variety of tools, including table saws, routers, sanders, and jointers. They interpret blueprints and specifications to ensure accurate construction. A strong understanding of wood properties, joinery techniques, and cabinet construction methods is essential. Precision and attention to detail are paramount to ensure the quality and structural integrity of the finished cabinets.

Machine Operators: CNC machine operators play a vital role in modern cabinet manufacturing. These individuals are responsible for setting up, operating, and maintaining computer-controlled machines that precisely cut and shape cabinet components. They must be capable of reading blueprints, interpreting G-code, and making adjustments to machine settings to ensure accurate and efficient production. Troubleshooting minor machine malfunctions and performing routine maintenance are also expected.

Finishers: Cabinet finishers are responsible for applying stains, paints, and protective coatings to cabinets. They need to have a thorough understanding of different finishing techniques, including spraying, brushing, and wiping. They must be able to prepare surfaces properly, mix coatings accurately, and apply them evenly to achieve the desired color, sheen, and durability. Knowledge of different types of coatings and their properties is important, as is the ability to identify and correct finishing defects.

Assemblers: Cabinet assemblers focus on putting together the various components of a cabinet, including the box, doors, drawers, and hardware. They use hand tools and power tools to fasten parts together accurately and efficiently. They must be able to follow assembly drawings and instructions carefully to ensure that the cabinets are assembled correctly and meet quality standards. This role often requires repetitive tasks and physical stamina.

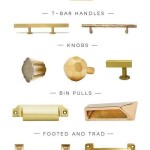

Hardware Installers: Hardware installers specialize in attaching hinges, handles, knobs, drawer slides, and other hardware components to cabinets. They must be able to use power drills, screwdrivers, and other tools to install hardware accurately and securely. They need to have a good understanding of different types of hardware and their proper installation methods. Attention to detail and precision are important to ensure that the hardware functions smoothly and enhances the aesthetic appearance of the cabinets.

Quality Control Inspectors: Quality control inspectors are responsible for inspecting cabinets at various stages of production to ensure that they meet quality standards. They check for defects in materials, workmanship, and finish. They use measuring tools and visual inspection techniques to identify any deviations from specifications. They document their findings and work with production staff to address any quality issues. This role requires a thorough understanding of cabinet construction, finishing techniques, and quality control procedures.

Beyond production roles, the design team plays a critical role in creating functional and aesthetically pleasing cabinet layouts. Designers use CAD software and their knowledge of kitchen design principles to develop custom cabinet plans that meet the specific needs of clients. Sales and marketing professionals focus on promoting and selling cabinets to customers, while management and administrative staff oversee the overall operations of the manufacturing facility.

Essential Skills and Qualifications

The specific skills and qualifications required for kitchen cabinet manufacturing jobs vary depending on the role. However, some fundamental skills are generally valued across different positions. These include:

Technical Skills: Proficiency in using hand tools and power tools is essential for many production roles. The ability to read blueprints, interpret technical drawings, and use measuring tools accurately is also crucial. For machine operators, knowledge of CNC programming and machine maintenance is required. Finishers need to be skilled in applying different types of coatings and using spray equipment.

Problem-Solving Skills: Cabinet manufacturing can involve complex tasks and unexpected challenges. Problem-solving skills are essential for identifying and resolving issues that arise during the production process. This may involve troubleshooting machine malfunctions, correcting finishing defects, or finding solutions to assembly problems.

Attention to Detail: Precision and accuracy are paramount in cabinet manufacturing. Attention to detail is crucial for ensuring that cabinets are constructed to exact specifications and meet quality standards. This involves carefully measuring and cutting materials, accurately assembling components, and paying close attention to finishing details.

Communication Skills: Effective communication is important for collaboration among team members and with supervisors. Clear communication is essential for understanding instructions, conveying information, and resolving conflicts. The ability to communicate effectively in both written and verbal form is highly valued.

Physical Stamina: Many cabinet manufacturing jobs require physical stamina and the ability to stand for extended periods of time. Workers may need to lift heavy materials, operate machinery, and perform repetitive tasks.体力 is essential for maintaining productivity and preventing injuries.

Formal education requirements vary depending on the role. Some entry-level positions may only require a high school diploma or equivalent, while more technical roles may require vocational training or an associate's degree. Apprenticeship programs can provide valuable on-the-job training and lead to skilled positions. Certifications in areas such as woodworking, finishing, or CNC operation can enhance job prospects.

Industry Trends and Future Outlook

The kitchen cabinet manufacturing industry is constantly evolving in response to changing consumer preferences, technological advancements, and economic conditions. Several key trends are shaping the industry's future:

Increased Demand for Customization: Consumers are increasingly seeking customized cabinet solutions that meet their specific needs and design preferences. This trend is driving the demand for skilled cabinet makers and designers who can create unique and personalized cabinet layouts. Manufacturers are adapting by offering more flexible design options and utilizing technology to facilitate the customization process.

Adoption of Automation Technologies: The integration of automation technologies, such as CNC machines, robotic arms, and automated finishing systems, is becoming more prevalent in cabinet manufacturing. These technologies can improve efficiency, reduce labor costs, and enhance product quality. As automation continues to advance, workers will need to develop skills in operating, maintaining, and programming automated equipment.

Focus on Sustainability: There is growing awareness of the environmental impact of cabinet manufacturing, leading to a greater focus on sustainability. Manufacturers are increasingly adopting sustainable practices, such as using eco-friendly materials, reducing waste, and conserving energy. Workers need to be knowledgeable about sustainable materials and practices and be committed to minimizing the environmental footprint of the industry.

Growth of Online Sales: Online sales of kitchen cabinets are increasing, providing consumers with greater access to a wider range of products and manufacturers. This trend is driving the need for online marketing and sales expertise within the industry. Manufacturers are investing in e-commerce platforms and digital marketing strategies to reach online customers.

The future outlook for kitchen cabinet manufacturing jobs is generally positive, driven by ongoing demand for new construction and renovation projects. However, the specific skills and qualifications required of workers are evolving in response to technological advancements and changing industry trends. Individuals seeking employment in this sector should focus on developing technical skills, problem-solving abilities, and a commitment to quality and sustainability.

In conclusion, the kitchen cabinet manufacturing industry offers a diverse range of job opportunities for individuals with different skill sets and experience levels. Understanding the various roles, essential skills, and industry trends is crucial for success in this dynamic and evolving sector.

Cabinetmaker Careers In Construction

Cabinet Maker Jobs In Sydney Available Now Hunter Labour Hire

Cabinet Maker What Is It And How To Become One Ziprecruiter

Cabinet Maker

Cabinetmaker Salary How To Become Job Description Best Schools

Cabinet Maker Jobs In Sydney Available Now Hunter Labour Hire

Working At Mka Cabinet Company Profile Information Hiredly Malaysia

Kitchen Cabinet Manufacturers Association Kcma Linkedin

Kitchen Bath Cabinet Manufacturing Friedman

Contemporary Style Wood Grain Melamine Hpl Kitchen Cabinets Customized For Jobs China Cabinet Made In Com

Related Posts