Kitchen Cabinet Ply Thickness: A Comprehensive Guide

The selection of appropriate materials for kitchen cabinets represents a crucial step in any kitchen renovation or construction project. Kitchen cabinets serve not only as storage solutions but also contribute significantly to the overall aesthetic and functionality of the kitchen space. Among the various materials used in cabinet construction, plywood stands out as a popular choice due to its strength, stability, and affordability. One of the most crucial aspects of plywood selection for kitchen cabinets is determining the optimal thickness. This article provides a detailed exploration of the factors influencing the choice of plywood thickness for kitchen cabinets, focusing on the implications for durability, cost, and overall cabinet performance.

Understanding the role of plywood in cabinet construction is essential before delving into specific thickness recommendations. Plywood is an engineered wood product composed of multiple layers of thin wood veneers, or plies, that are bonded together with adhesive. These plies are arranged with their grain alternating to provide exceptional strength and dimensional stability. This cross-graining method effectively resists warping, cracking, and shrinking, making plywood a superior alternative to solid wood for many cabinet components. The thickness of the plywood directly affects its load-bearing capacity, resistance to deformation, and overall lifespan. Therefore, careful consideration of plywood thickness is paramount for ensuring the longevity and functionality of kitchen cabinets.

The selection process involves evaluating the specific application within the cabinet structure, such as cabinet boxes, shelves, doors, and backs. Each of these components requires different levels of strength and stability, which, in turn, dictates the need for varying plywood thicknesses. Furthermore, understanding the different grades and types of plywood is crucial, as these factors also play a significant role in the overall performance of the cabinets. The following sections will elaborate on the key considerations necessary for making informed decisions about plywood thickness for kitchen cabinets.

Key Point 1: Determining Plywood Thickness Based on Cabinet Component

Different components of kitchen cabinets require varying degrees of structural support and resistance to stress. Consequently, the optimal plywood thickness will differ depending on the intended application. The main components to consider are the cabinet boxes (sides, top, bottom), shelves, cabinet backs, and doors.

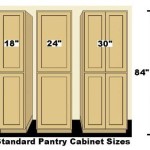

Cabinet Boxes: The cabinet box, encompassing the sides, top, and bottom panels, forms the foundational structure of the cabinet. These components bear the weight of the contents stored within the cabinets, as well as the weight of the countertop in the case of base cabinets. For base cabinets, which are subjected to greater loads and stresses, a plywood thickness of at least 3/4 inch (19mm) is generally recommended. This thickness provides sufficient strength and rigidity to support heavy items and prevent sagging or deformation over time. Upper cabinets, which typically hold lighter items, can often utilize plywood with a thickness of 1/2 inch (12mm) or 5/8 inch (16mm). However, for upper cabinets designed to support particularly heavy items, such as microwave ovens or large quantities of dishware, 3/4 inch plywood remains a preferable option. The choice also depends on the cabinet's span – longer spans will require thicker plywood to prevent sagging.

Shelves: Shelves are another critical component that must withstand significant loads. The appropriate plywood thickness for shelves depends primarily on the length of the shelf and the anticipated weight of the stored items. For shorter shelves spanning less than 36 inches, a 1/2 inch (12mm) or 5/8 inch (16mm) plywood may suffice. However, for longer shelves exceeding 36 inches, a minimum of 3/4 inch (19mm) plywood is strongly recommended to prevent sagging under load. To further enhance the load-bearing capacity of shelves, consider incorporating a solid wood edging along the front edge of the shelf. This edging acts as a stiffener, providing additional support and minimizing deflection. Another option for maximizing shelf strength is to use thicker plywood or implement a shelf support system, such as metal shelf supports or adjustable shelf pins.

Cabinet Backs: The primary function of the cabinet back is to provide structural integrity and to prevent the cabinet box from racking, or distorting out of square. While the back panel does not typically bear the weight of stored items directly, it plays a crucial role in maintaining the overall stability of the cabinet. For most kitchen cabinets, a plywood thickness of 1/4 inch (6mm) or 3/8 inch (9mm) is adequate for the back panel. However, for larger or heavier cabinets, particularly those designed to hold appliances or other heavy items, a thicker back panel of 1/2 inch (12mm) may be preferable. Using a full back, rather than a partial back, will also increase the cabinet's rigidity. It's essential to securely fasten the back panel to the cabinet box using screws or nails to ensure a strong and stable connection.

Cabinet Doors: Cabinet doors generally require less structural strength compared to other cabinet components. The primary considerations for door thickness are stability and aesthetic appeal. Plywood thicknesses ranging from 1/4 inch (6mm) to 3/4 inch (19mm) can be used for cabinet doors, depending on the door style and construction method. For flat-panel doors, a 1/4 inch or 3/8 inch plywood core veneered with a decorative wood veneer or laminate is a common choice. For raised-panel doors, a thicker plywood, such as 1/2 inch or 3/4 inch, may be used to provide adequate support for the raised panel. Frame-and-panel doors, which consist of a solid wood frame surrounding a plywood panel, also offer a durable and aesthetically pleasing option. In these cases, the thickness of the plywood panel is typically less critical than the quality and construction of the frame.

Key Point 2: Understanding Plywood Grades and Types

Besides thickness, the grade and type of plywood significantly impact its suitability for kitchen cabinet construction. Plywood grades are determined by the quality of the surface veneers, while plywood types are categorized based on the adhesive used to bond the plies together.

Plywood Grades: Plywood is graded based on the appearance and quality of the face veneers, with higher grades indicating fewer defects and a smoother surface. Common plywood grades include: A, B, C, and D. "A" grade plywood exhibits the highest quality veneer, with minimal knots or imperfections. "B" grade plywood may have a few minor knots or repairs. "C" grade plywood contains more knots and imperfections, while "D" grade plywood is the lowest quality, with large knots and potential voids. For exposed cabinet surfaces, such as doors and finished cabinet sides, "A" or "B" grade plywood is generally preferred to ensure a smooth and visually appealing finish. For interior cabinet components, such as shelves and cabinet backs, "C" or "D" grade plywood may be acceptable, provided that the surface is not visible and the structural integrity is not compromised.

Plywood Types: Plywood is also classified based on the type of adhesive used to bond the plies together. The adhesive determines the plywood's moisture resistance and suitability for different environments. Common plywood types include: Interior, Exterior, and Marine grade. Interior plywood uses a water-resistant adhesive and is suitable for indoor applications where moisture exposure is minimal. Exterior plywood uses a waterproof adhesive and is designed to withstand exposure to moisture and humidity. Marine grade plywood utilizes a high-quality waterproof adhesive and is specifically intended for use in marine environments, where it is subjected to constant exposure to water. For kitchen cabinets, which are exposed to varying levels of humidity and potential spills, Exterior grade plywood is highly recommended. While Marine grade plywood offers superior moisture resistance, it is typically more expensive and may not be necessary for most kitchen cabinet applications. Interior grade plywood should be avoided in kitchen cabinet construction due to its limited moisture resistance and susceptibility to warping or delamination.

Furthermore, consider the wood species used for the plywood veneers. Common wood species for plywood used in kitchen cabinets include: Birch, Maple, Oak, and Poplar. Birch plywood is known for its smooth surface and uniform grain pattern, making it a versatile choice for both painted and stained finishes. Maple plywood offers a similar appearance to birch but is slightly harder and more durable. Oak plywood is characterized by its distinctive grain pattern and is often used for cabinets with a traditional or rustic aesthetic. Poplar plywood is a softer and less expensive option, often used for paint-grade cabinets or for interior cabinet components.

Key Point 3: Cost Considerations and Installation Factors

The selection of plywood thickness for kitchen cabinets also necessitates a careful evaluation of cost implications and installation considerations. Thicker plywood typically costs more than thinner plywood, so it's important to strike a balance between structural performance and budget constraints.

Cost Factors: The cost of plywood depends on several factors, including: thickness, grade, type, wood species, and availability. Thicker plywood requires more raw materials and manufacturing processes, resulting in a higher price. Higher-grade plywood, with fewer defects and a smoother surface, also commands a premium price. Exterior and Marine grade plywood, with their waterproof adhesives, are more expensive than Interior grade plywood. Certain wood species, such as Maple and Oak, may be more costly than others, such as Poplar or Birch. When planning a kitchen cabinet project, it's essential to obtain quotes from multiple suppliers to compare prices and find the best value for the required plywood thickness, grade, and type. Consider optimizing the use of plywood by using thicker grades for critical structural components and thinner grades for less demanding applications.

Installation Factors: The choice of plywood thickness can also impact the ease and complexity of cabinet installation. Thicker plywood is generally heavier and more difficult to handle, requiring more manpower or specialized equipment for installation. Thinner plywood, while lighter and easier to work with, may be more susceptible to damage during installation. The type of fasteners used to assemble the cabinets also depends on the plywood thickness. Thicker plywood requires longer screws or nails to ensure a secure connection, while thinner plywood may require more delicate fasteners to avoid splitting or damaging the material. It's important to carefully consider the installation process and choose a plywood thickness that can be readily handled and fastened with the available tools and resources.

Moreover, consider the type of joinery used in cabinet construction. Different joinery methods, such as: butt joints, dado joints, and dovetail joints, require different levels of precision and material thickness. Thicker plywood may be necessary for certain joinery methods to ensure a strong and durable connection. For example, dado joints, which involve cutting a groove into one piece of plywood to receive another, benefit from thicker plywood to provide adequate material for the groove. Dovetail joints, known for their exceptional strength and aesthetic appeal, also require thicker plywood to accommodate the interlocking dovetail pins and tails. The choice of joinery method will influence the optimal plywood thickness and the overall strength and stability of the cabinet.

In summary, selecting the appropriate plywood thickness for kitchen cabinets is a multifaceted decision that requires careful consideration of the intended application, structural requirements, cost implications, and installation factors. By understanding the role of plywood in cabinet construction, evaluating the different components, considering the plywood grades and types, and accounting for cost and installation considerations, informed decisions can be made ensuring the longevity, functionality, and aesthetic appeal of kitchen cabinets. Investing time and effort in selecting the right plywood thickness will ultimately contribute to a successful and satisfying kitchen renovation or construction project.

Cabinet Quality Kitchen Rta Cabinets Orange County Pre Made Whole Quartz Countertop Slab Prefab Granite Installation

Cabinet Composition What Makes A High Quality

Choosing The Best Type Of Plywood For Cabinets Columbia Forest S

Which Plywood Is Best For Modular Kitchen Designcafe

Which Plywood Is Best For Modular Kitchen Designcafe

Selecting Hardwood Plywood For Cabinetry Columbia Forest S

Which Plywood Is Best For Modular Kitchen Designcafe

What Size Plywood Should You Use To Build Cabinets Ehow

Choosing The Best Type Of Plywood For Cabinets Columbia Forest S

Which Plywood Is Best For Modular Kitchen Designcafe

Related Posts