Make Your Own Kitchen Cabinet Doors: MDF

Medium-density fiberboard (MDF) offers an economical and versatile substrate for crafting custom kitchen cabinet doors. Its smooth, uniform surface makes it ideal for painting, and its stability resists warping and cracking. This guide outlines the process of creating MDF cabinet doors, empowering homeowners to personalize their kitchens without the expense of professionally manufactured doors.

Material Selection and Preparation: Selecting the correct MDF thickness is crucial. While thinner sheets are easier to work with, they may lack the necessary rigidity for larger doors. A thickness of ¾ inch (19mm) generally provides a good balance between workability and durability. Ensure the MDF is furniture-grade and free from significant imperfections. Proper acclimation of the MDF to the workshop environment minimizes the risk of later movement or distortion. Allow the material to sit in the room for at least 24 hours before beginning construction.

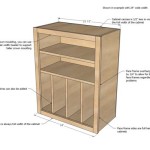

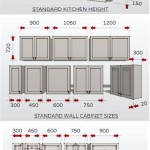

Design and Measurement: Accurate measurements are paramount to a successful outcome. Carefully measure existing cabinet openings, accounting for desired overlay and reveals. Sketching the door design, including any panel details or decorative elements, helps visualize the finished product and facilitates precise cutting. Software applications dedicated to cabinet design can assist in generating detailed plans and cut lists, reducing waste and ensuring accuracy.

Cutting the MDF: A table saw equipped with a sharp, fine-tooth blade delivers the cleanest cuts. Support large sheets of MDF with outfeed rollers or an assistant to prevent binding and splintering. When cutting intricate shapes or profiles, a jigsaw fitted with a high-quality MDF blade offers greater versatility and precision. Always wear appropriate safety glasses and a dust mask when working with MDF.

Creating Panel Details (Optional): Raised panel designs add a touch of elegance to cabinet doors. A router table equipped with a panel-raising bit allows for the creation of consistent, professional-looking profiles. Alternatively, decorative molding can be applied to the surface of the MDF to simulate a raised panel effect. Ensure accurate measurements and test cuts on scrap material before proceeding with the final door panels.

Assembling the Doors: For frame-and-panel doors, wood glue and clamps provide a strong and durable bond. Apply glue evenly to the mating surfaces and clamp firmly, ensuring proper alignment. Allow adequate drying time before removing clamps. For slab-style doors, edge banding is applied to conceal the raw MDF core. Iron-on edge banding offers a convenient and readily available solution. Apply even pressure with a specialized edge banding tool or a household iron to activate the adhesive.

Finishing the Doors: MDF’s smooth surface accepts paint readily, making it an ideal canvas for various finishes. A primer specifically designed for MDF seals the surface and promotes paint adhesion. Apply multiple thin coats of paint, allowing ample drying time between each application. Sand lightly between coats with fine-grit sandpaper to achieve a smooth, professional finish. Alternative finishing options include staining, veneering, and laminating.

Hardware Installation: Precisely locate and drill holes for hinges, handles, and other hardware. Use Forstner bits for creating clean, accurate holes for recessed hardware. Ensure the hardware complements the overall design aesthetic of the kitchen cabinets. High-quality hardware enhances both the appearance and functionality of the finished doors.

Installation: Hang the finished doors using appropriate hinges, adjusting for proper alignment and spacing. Ensure the doors swing freely and close smoothly. Final adjustments may be necessary to achieve optimal functionality and a cohesive appearance. Regular maintenance, including cleaning and lubrication of hinges, will prolong the lifespan of the cabinet doors.

Safety Considerations: Working with MDF generates fine dust particles that can be harmful if inhaled. Always wear a properly fitted respirator or dust mask when cutting or sanding MDF. Adequate ventilation in the workspace is essential to minimize dust accumulation. Safety glasses should be worn at all times to protect eyes from flying debris. Follow manufacturer's instructions for all tools and materials to ensure safe operation.

Making Mdf Cabinet Doors Woodworking

How To Make Your Own Cabinet Doors Beneath My Heart

How To Make Your Own Cabinet Doors Beneath My Heart Kitchen Cabinets Decor Mdf Diy Makeover

How To Build Cabinet Doors Update Your Cabinets Or Built Ins

Diy Rustic Industrial Cabinet Doors Tutorial Cherished Bliss

How To Make Your Own Cabinet Doors Beneath My Heart

Cupboard Doors Mdf Bespoke Kitchens Manufacturer

How To Make Shaker Style Kitchen Cabinet Doors On A Budget My Design Rules

Mdf Kitchen Cabinets All You Need To Know

Mdf Kitchen Cabinets All You Need To Know

Related Posts