Standard Kitchen Cabinet Door Thickness: A Comprehensive Guide

The dimensions of kitchen cabinet doors play a crucial role in the overall aesthetics, functionality, and durability of kitchen cabinetry. While various measurements are important, the thickness of the door is a fundamental factor influencing its structural integrity and visual appeal. Understanding standard cabinet door thicknesses and the considerations that dictate their selection is essential for homeowners, contractors, and cabinet makers alike.

Cabinet door thickness directly relates to the perceived quality and longevity of the cabinetry. A door that is too thin might warp or sag over time, especially if exposed to moisture or weight. Conversely, an excessively thick door can be unwieldy and potentially strain the hinges and cabinet frame. Therefore, a balanced approach is required to ensure a durable and aesthetically pleasing result.

The typical range for kitchen cabinet door thickness falls between ¾ inch (19.05 mm) and 1 inch (25.4 mm). This range offers a good compromise between structural strength and weight. However, variations do exist based on factors such as the door style, material, and design considerations. This article delves into the nuances of standard kitchen cabinet door thickness, exploring the typical measurements, influencing factors, and best practices for ensuring optimal results.

Common Thickness Measurements and Their Applications

The ¾ inch (19.05 mm) thickness is the most frequently encountered standard for kitchen cabinet doors. This measurement provides a suitable level of strength for most door styles and materials, making it a versatile and cost-effective choice. Cabinet doors of this thickness are common in both stock and semi-custom cabinetry. This thickness also allows for a wide range of hardware options, as it provides sufficient material for secure screw placement for hinges and handles.

Doors measuring 1 inch (25.4 mm) in thickness are typically found in higher-end or custom cabinetry. The added thickness imparts a sense of solidity and quality, making the doors feel more substantial. This increased thickness is particularly beneficial for larger or heavier doors, as it reduces the risk of warping or sagging. It also allows for more elaborate detailing, such as deeper panels or more intricate profiles. The use of 1-inch thick doors often suggests a superior level of craftsmanship and durability.

While ¾ inch and 1 inch are the most common, other less frequent thicknesses may be encountered. For example, ½ inch (12.7 mm) thick doors may be used in certain budget-friendly or contemporary designs, particularly for frameless cabinets where the door's edges are visible. However, these thinner doors may require additional reinforcement or support to prevent warping. In some very high-end custom applications, cabinet doors may exceed 1 inch in thickness, but this is relatively rare due to the increased weight and cost involved.

When selecting a cabinet door thickness, it is important to consider the overall design and style of the kitchen. A sleek, modern kitchen might benefit from thinner doors, while a more traditional kitchen might be enhanced by thicker, more substantial doors. Additionally, the thickness of the doors should be consistent throughout the entire kitchen to maintain a cohesive and balanced aesthetic.

Factors Influencing Cabinet Door Thickness

Several factors influence the appropriate thickness for kitchen cabinet doors, including the material used, the door style, and the cabinet construction type. Understanding these factors is crucial for making informed decisions and ensuring long-lasting, functional cabinetry.

Material selection plays a significant role. Solid wood doors, due to the natural properties of wood, may require a greater thickness to prevent warping or splitting, especially if the wood is not properly kiln-dried or seasoned. Engineered wood products, such as MDF (Medium-Density Fiberboard) or plywood, tend to be more stable and less prone to warping than solid wood. Therefore, doors made from these materials may be acceptable at a thinner dimension without compromising structural integrity. MDF is particularly favored for painted cabinet doors because of its smooth surface and resistance to expansion and contraction due to humidity changes.

The style of the cabinet door also affects the appropriate thickness. Slab doors, which are flat and featureless, can often be thinner than doors with raised panels or intricate detailing. Raised panel doors, with their recessed or raised center panels, require sufficient thickness to accommodate the panel and the surrounding frame. The thickness of the frame must also be sufficient to withstand the stresses imposed by the panel and the hardware. Similarly, shaker-style doors, with their simple recessed panel and flat frame, require a certain thickness to maintain their clean lines and structural stability.

The type of cabinet construction, whether framed or frameless, can also influence the optimal door thickness. Framed cabinets, with their face frame providing additional support, often allow for slightly thinner doors compared to frameless cabinets. Frameless cabinets, also known as European-style cabinets, rely on the cabinet box itself for structural support, requiring the doors to be more robust. In frameless construction, the door edges are typically exposed, further emphasizing the need for a higher quality material and construction method.

The size of the cabinet door should also be taken into consideration. Larger doors, particularly those exceeding 30 inches in height or width, are more susceptible to warping or sagging. Therefore, larger doors typically require a greater thickness to ensure stability. In some cases, additional support, such as a metal stiffener, may be necessary to prevent warping in very large doors.

Finally, the weight of the hardware selected, such as heavy knobs or pulls, should be considered. Heavier hardware can place additional stress on the cabinet door, potentially leading to sagging or damage over time. Using thicker doors or reinforcing the mounting points can help to address this issue.

Ensuring Proper Installation and Longevity

Selecting the correct cabinet door thickness is only part of the equation. Proper installation and ongoing maintenance are essential for ensuring the longevity and optimal performance of kitchen cabinetry. Incorrect installation can negate the benefits of even the highest quality doors, while neglecting maintenance can lead to premature wear and tear.

Accurate hinge placement is critical for proper door alignment and smooth operation. Hinges must be securely fastened to both the cabinet frame and the door itself. The type of hinge selected should be appropriate for the weight and thickness of the door. For heavier or thicker doors, heavy-duty hinges are recommended. Proper hinge alignment prevents binding and ensures that the door closes evenly and securely.

Adequate clearance between the door and the cabinet frame is also necessary. Insufficient clearance can cause the door to rub against the frame, leading to scratches and premature wear. Excessive clearance, on the other hand, can create unsightly gaps and compromise the cabinet's seal. Adjusting the hinges can often correct minor alignment issues, but more significant problems may require shimming or replacing the hinges altogether.

Proper sealing and finishing are crucial for protecting the cabinet doors from moisture and damage. Moisture can cause wood to warp, swell, or rot. Applying a high-quality finish, such as paint, stain, or varnish, can create a protective barrier against moisture and other environmental factors. All surfaces of the door, including the edges and back, should be properly sealed to ensure maximum protection.

Regular cleaning and maintenance can also extend the lifespan of kitchen cabinet doors. Cleaning spills and splatters promptly can prevent stains and damage. Using appropriate cleaning products and avoiding harsh chemicals can help to protect the finish. Periodically inspecting the hinges and hardware can identify potential problems before they escalate.

Climate control within the kitchen can also impact the longevity of cabinet doors. Maintaining a consistent temperature and humidity level can minimize the risk of warping or cracking. Avoiding extreme temperature fluctuations and ensuring adequate ventilation can help to protect the cabinetry from damage.

In cases where a door does warp or sag, repairs may be possible. Small warps can sometimes be corrected by applying weight or moisture to the affected area. Sagging doors may be reinforced with metal stiffeners or by replacing the hinges with heavier-duty versions. However, in some cases, replacing the door may be the most cost-effective solution.

When replacing cabinet doors, it is important to ensure that the new doors are compatible with the existing cabinet frame and hardware. Replacing all the doors at once can ensure a consistent appearance and prevent mismatched styles or finishes. Consulting with a professional cabinet maker or installer can help to ensure a successful replacement project.

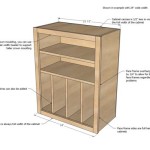

Proper Depth For Frameless Cabinets

Cabinet Composition What Makes A High Quality

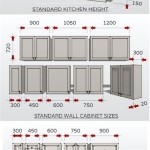

N Standard Kitchen Dimensions Renomart

Kitchen Cabinet Refacing Door Depot

Door Dimensions And Hinge Requirements

N Standard Kitchen Dimensions Renomart

Kitchen Cabinet Dimensions

N Standard Kitchen Dimensions Renomart

Kitchen Standard Base Cabinets

How To Build Cabinet Doors Sawdust Girl