Unfinished Kitchen Cabinets Fort Worth: A Comprehensive Guide

Fort Worth, Texas, presents a dynamic market for home renovation and construction projects. Within this market, unfinished kitchen cabinets represent a cost-effective and customizable option for homeowners and contractors alike. The appeal lies in the ability to personalize the cabinets to match specific design aesthetics and functional requirements, a particularly attractive feature in a city with diverse architectural styles and individual preferences.

Unfinished kitchen cabinets, as the name suggests, are cabinets delivered without a factory-applied finish. This means they arrive ready for painting, staining, or other forms of surface treatment. The raw material, typically wood or a wood-based composite, is exposed, providing a blank canvas for customization. Choosing unfinished cabinets in Fort Worth involves careful consideration of material quality, construction methods, and the intended finishing process.

The availability of unfinished cabinets in Fort Worth varies, ranging from local cabinet makers to national retailers. Each source offers different levels of service, pricing, and customization options. Understanding these differences is crucial for making an informed decision that aligns with both budgetary constraints and aesthetic goals.

Key Point 1: The Advantages of Choosing Unfinished Cabinets

The primary advantage of opting for unfinished kitchen cabinets resides in the control over the final appearance. Homeowners are not limited to the pre-determined colors and finishes offered by manufacturers of pre-finished cabinets. One can select any paint color imaginable or choose a stain that perfectly complements existing flooring, countertops, or other elements in the kitchen design. This level of customization is particularly valuable when aiming for a unique or highly personalized kitchen space. Furthermore, matching existing cabinetry in older homes is significantly easier with unfinished options.

Cost savings also represent a significant benefit. Unfinished cabinets generally have a lower upfront cost compared to their pre-finished counterparts. This difference in price allows homeowners to allocate more budget towards higher-quality hardware, countertops, or other kitchen upgrades. The labor cost associated with finishing the cabinets can be managed through DIY efforts or by hiring professional painters, offering another level of cost control.

Another advantage lies in the ability to inspect the quality of the cabinet construction. With unfinished cabinets, the underlying wood and joinery are visible, allowing for a thorough assessment of the materials and craftsmanship. This transparency can provide greater confidence in the longevity and durability of the cabinets. Any imperfections in the wood can be addressed before the finishing process begins, ensuring a smooth and flawless final result.

Flexibility also plays a role. If design preferences change during the renovation process, it is easier to adapt the finish of unfinished cabinets. Altering a paint color or stain is a relatively straightforward task compared to replacing pre-finished cabinets altogether. This adaptability provides peace of mind and safeguards against potential design regrets. Moreover, should accidental damage occur after installation, repairing and re-finishing a section of unfinished cabinetry is often simpler and less costly than sourcing replacement parts or refinishing pre-finished cabinets.

Key Point 2: Material Considerations and Construction Quality

The material used in the construction of unfinished cabinets significantly impacts their durability, appearance, and the ease with which they can be finished. Common materials include solid wood, plywood, medium-density fiberboard (MDF), and particleboard. Each material has its own set of characteristics, advantages, and disadvantages.

Solid wood is generally considered the premium option, offering superior strength and a natural aesthetic. Hardwoods such as maple, oak, and cherry are commonly used for cabinet construction due to their inherent durability and resistance to wear and tear. Solid wood cabinets tend to be more expensive than those made from other materials, but they offer a long-lasting and visually appealing solution. The grain pattern of solid wood adds character and warmth to the kitchen space.

Plywood is an engineered wood product composed of layers of wood veneer glued together. It offers good strength and stability at a lower cost than solid wood. High-quality plywood is less prone to warping or cracking than solid wood, making it a suitable option for cabinet boxes and shelves. Plywood also provides a smooth surface for painting or staining.

MDF is another engineered wood product made from wood fibers that have been compressed and bonded together with resin. It offers a very smooth and uniform surface, making it an excellent choice for painted cabinets. MDF is less susceptible to expansion and contraction due to changes in humidity compared to solid wood, reducing the risk of cracks or warping. However, MDF is heavier than solid wood or plywood and may not be as durable in high-moisture environments.

Particleboard is the least expensive option, consisting of wood particles glued together under pressure. While particleboard is suitable for some cabinet components, it is generally not recommended for high-stress areas or in kitchens prone to moisture. Particleboard is also less durable than solid wood, plywood, or MDF and may be more susceptible to damage from impacts or heavy loads.

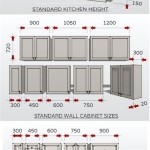

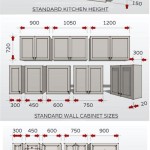

Construction quality is as important as the material selection. Dovetail joints, mortise-and-tenon joints, and sturdy screws are indicators of well-constructed cabinets. Avoid cabinets with flimsy construction or poorly aligned doors and drawers. The back panels should be securely attached and made from a durable material. Examine the drawer slides and hinges to ensure they are smooth and reliable. These seemingly minor details contribute significantly to the overall quality and longevity of the cabinets.

Key Point 3: Finishing Techniques and Considerations for Fort Worth Climate

The finishing process is crucial for protecting unfinished cabinets and achieving the desired aesthetic. The choice between painting and staining depends on personal preference and the overall design of the kitchen. Painting provides a solid, opaque color, while staining enhances the natural grain of the wood.

Before applying any finish, the cabinets must be properly prepared. This includes sanding all surfaces to create a smooth and even base. Any imperfections, such as knots or dents, should be filled with wood filler and sanded smooth. Thorough cleaning is essential to remove dust and debris, ensuring proper adhesion of the finish.

For painted cabinets, a primer coat is recommended to seal the wood and provide a uniform surface for the paint. High-quality acrylic latex paints are a good choice for kitchen cabinets due to their durability and ease of cleaning. Multiple coats of paint may be required to achieve full coverage and a professional-looking finish. Using a brush, roller, or sprayer depends on the desired texture and the size of the project. Spraying generally provides the smoothest finish, but it requires specialized equipment and skill.

For stained cabinets, the stain should be applied evenly and allowed to penetrate the wood for the recommended time. Excess stain should be wiped off to prevent a blotchy or uneven appearance. After the stain has dried completely, a clear topcoat is necessary to protect the wood and enhance its durability. Polyurethane is a popular choice for kitchen cabinets due to its resistance to water, scratches, and stains. Several coats of polyurethane may be necessary to provide adequate protection.

The climate in Fort Worth presents specific challenges for finishing kitchen cabinets. High humidity levels can affect the drying time of paints and stains, and extreme temperature fluctuations can cause wood to expand and contract, potentially leading to cracks or warping. It is important to choose finishes that are specifically designed for humid environments and to allow sufficient drying time between coats. Proper ventilation is also crucial during the finishing process to ensure that fumes are properly dissipated and to prevent moisture buildup. Consideration should also be given to the UV resistance of the chosen finish as sunlight exposure can cause fading or discoloration over time.

The selection of appropriate tools and equipment is crucial for a successful finishing project. High-quality brushes, rollers, sandpaper, and sprayers can significantly impact the final result. Proper safety gear, such as respirators, gloves, and eye protection, should always be worn during the finishing process to protect against harmful chemicals and fumes. Seeking professional assistance for the finishing process is a viable option for those who lack the necessary skills or equipment. A professional painter or cabinet finisher can ensure a flawless and durable finish that will enhance the beauty and longevity of the kitchen cabinets.

Ultimately, the decision to use unfinished kitchen cabinets in Fort Worth requires careful planning and execution. By considering the advantages, selecting the right materials, and employing proper finishing techniques, homeowners can create a customized kitchen space that reflects their individual style and preferences while staying within budget.

Fort Worth Custom Cabinetry Cabinet Installation Design Services

Unfinished Kitchen Cabinets Builder S Discount Center

Fort Worth Custom Cabinetry Cabinet Installation Design Services

Builders Surplus Unfinished Kitchen Cabinets Yee Haa

Builders Surplus Unfinished Kitchen Cabinets Yee Haa

Builders Surplus Unfinished Kitchen Cabinets Yee Haa

2024 Kitchen Cabinet Installation Homeadvisor

Hampton Bay Easthaven Assembled 12x34 5x24 In Frameless Base Cabinet With Drawer Unfinished Beech Eh1235b Gb The Home Depot

Builders Surplus Olde World Collection Yee Haa

The Best 10 Cabinetry In Denton Tx Last Updated October 2024 Yelp

Related Posts