What Tools Are Needed To Install Kitchen Cabinets

Installing kitchen cabinets is a significant undertaking that requires more than just brute strength. Successful installation hinges on precision, accuracy, and the proper tools. Having the right tools readily available will streamline the process, ensure professional-looking results, and minimize the risk of errors that can lead to costly rework. This article details the essential tools required for installing kitchen cabinets, categorized for clarity and emphasizing their specific purposes.

Measuring and Leveling Tools

Accurate measurements and precise leveling are the foundational elements of a well-installed kitchen. Without these, cabinets will be misaligned, creating gaps, uneven surfaces, and functional problems with doors and drawers. These tools ensure the cabinets are aesthetically pleasing and operate as intended.

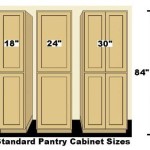

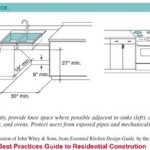

Tape Measure: A standard tape measure, preferably 25 feet or longer, is crucial for determining wall lengths, cabinet heights, appliance spaces, and overall layout configurations. Accurate measurements, typically recorded to the nearest 1/8 inch, are indispensable for proper cabinet placement and fitting filler pieces.

Laser Level: A laser level projects a perfectly horizontal or vertical line, offering a significant advantage over traditional spirit levels, especially when dealing with long walls or multiple cabinets. It ensures that base cabinets are level across the floor and that upper cabinets are aligned at the same height. Some laser levels feature plumb (vertical) lines, which are particularly useful for aligning cabinet faces and ensuring they are perfectly perpendicular to the floor. Using a laser level can prevent issues that arise from relying solely on bubble levels, which can sometimes be less accurate over extended distances.

Spirit Level: In addition to a laser level, a traditional spirit level is necessary for smaller-scale adjustments and checking the levelness of individual cabinet components, such as shelves and doors. A 4-foot level is useful for checking larger sections, while a smaller 2-foot level is ideal for tight spaces. It's always good practice to double-check the laser level with a spirit level to ensure accuracy.

Stud Finder: Identifying wall studs is essential for securely attaching cabinets to the wall. A quality stud finder, preferably one that also detects electrical wiring and plumbing, will help locate the studs behind the drywall. This prevents damage to concealed utilities and ensures that the cabinets are anchored to solid framing for maximum stability. Electronic stud finders are generally more accurate than magnetic ones, especially on walls with textured surfaces or multiple layers of drywall.

Measuring Squares: A combination square and a speed square are invaluable for marking accurate angles and ensuring that cabinet corners are square. This is important for framing, installing filler panels, and verifying the squareness of the walls themselves. Using a measuring square helps avoid gaps and misalignments, contributing to a professional finish.

Cutting and Drilling Tools

Altering cabinets to fit the kitchen's unique dimensions often requires precise cutting and drilling. Having the appropriate cutting and drilling tools enables accurate modifications to cabinet components and simplifies the process of creating pilot holes for screws and fasteners. The following tools are crucial for achieving professional results.

Circular Saw: A circular saw is essential for cutting cabinet panels, filler pieces, and scribe moldings to the required size. A fine-tooth blade designed for plywood or hardwoods will minimize splintering and produce clean cuts. Using a guide, such as a straight edge clamped to the workpiece, will ensure straight, accurate cuts. Cordless circular saws offer greater mobility, while corded saws typically provide more power for denser materials.

Miter Saw: A miter saw is specifically designed for making precise angled cuts, which are often necessary for installing crown molding, baseboards, and other decorative trim. A compound miter saw allows for both miter (angle across the face) and bevel (angle through the thickness) cuts, offering versatility for a wide range of woodworking tasks. A sliding miter saw further increases cutting capacity, enabling wider pieces to be cut accurately.

Jigsaw: A jigsaw is useful for making curved or irregular cuts, such as cutting openings for sinks or appliances. Using a blade designed for cutting wood or laminate, depending on the material, will ensure clean cuts and minimize chipping. A variable-speed jigsaw allows for better control when cutting different materials, preventing overheating and ensuring a smooth finish.

Drill/Driver: A cordless drill/driver is indispensable for driving screws and drilling pilot holes. A variable-speed drill allows for precise control, preventing screws from stripping or damaging the cabinet material. Having a set of drill bits, including countersink bits, ensures that pilot holes are the correct size for the screws being used. Impact drivers can provide extra torque for driving long screws into dense wood, making them particularly useful for attaching cabinets to wall studs.

Hole Saw Kit: A hole saw kit is necessary for drilling holes for plumbing pipes, electrical wiring, and other services. Different sizes of hole saws are needed to accommodate various pipe diameters and wiring conduits. Using a hole saw guide can help maintain accuracy and prevent the saw from wandering.

Fastening and Installation Tools

Securing the cabinets to the wall and connecting them together requires the right fasteners and tools for driving them. These tools ensure that the cabinets are securely mounted and aligned, providing a stable and functional kitchen.

Cabinet Screws: High-quality cabinet screws, typically with a self-tapping design, are essential for attaching cabinets to the wall studs. These screws are designed to provide a strong, secure hold without splitting the wood. Different lengths of screws may be needed depending on the thickness of the cabinet back and the wall material.

Shims: Shims are thin, tapered pieces of wood or plastic that are used to level cabinets, fill gaps, and create a perfectly flush surface. They are especially useful when dealing with uneven floors or walls. A variety of shim sizes should be on hand to accommodate different gap widths. Plastic shims are often preferred over wood shims because they are less likely to compress or warp over time.

Clamps: Clamps are essential for holding cabinets together while they are being screwed or glued. Face frame clamps are specifically designed to hold cabinet face frames tightly together, ensuring a seamless joint. Pipe clamps can be used to apply pressure to larger sections of cabinets. Having a variety of clamp sizes and types will make the installation process easier and more efficient.

Caulk Gun: A caulk gun is used to apply caulk to seal gaps between the cabinets and the walls, countertops, or floor. A smooth bead of caulk will create a waterproof seal and give the installation a finished look. Using a high-quality caulk that is paintable and mildew-resistant is recommended.

Nail Gun (Optional): A nail gun, particularly a brad nailer or finish nailer, can be useful for attaching trim pieces, scribe moldings, and decorative elements to the cabinets. A nail gun provides a quick and efficient way to secure these components without the need for pilot holes. Using the correct nail size and pressure setting will prevent the nails from penetrating too deeply or splitting the wood.

Additional Essential Tools

Beyond the core tools, several other items are essential for a smooth and efficient cabinet installation. These tools contribute to safety, accuracy, and overall project management.

Safety Glasses: Protecting eyesight is paramount when working with power tools. Safety glasses should be worn at all times to prevent debris from entering the eyes.

Dust Mask: Cutting and sanding cabinet materials can generate significant amounts of dust. A dust mask or respirator will protect the respiratory system from inhaling harmful particles.

Work Gloves: Work gloves provide a better grip on tools and materials, and they protect hands from splinters, cuts, and abrasions. Choosing gloves that fit well and allow for dexterity is important.

Pencil and Marking Tools: A sharp pencil, a marking knife, and a set of colored pencils are essential for marking cut lines, identifying stud locations, and making other notations on the cabinets and walls.

Utility Knife: A utility knife is useful for a variety of tasks, such as scoring drywall, trimming shims, and opening boxes. A sharp blade is essential for clean, accurate cuts.

Putty Knife and Wood Filler: A putty knife is used to apply wood filler to fill nail holes, screw holes, and other imperfections in the cabinets. Sanding the filler smooth after it dries will create a seamless surface.

Touch-Up Paint or Stain: Touch-up paint or stain is used to conceal minor scratches, chips, and other blemishes on the finished cabinets. Matching the color and finish of the cabinets is essential for a professional look.

Shop Vacuum: A shop vacuum is essential for cleaning up dust and debris throughout the installation process. Keeping the work area clean will improve visibility, reduce the risk of accidents, and create a more pleasant working environment.

Crowbar and Pry Bar: These tools are useful for removing existing cabinets or trim and for making minor adjustments to cabinet placement. Be careful not to damage the surrounding walls or surfaces when using these tools.

Cabinet Jack: A cabinet jack is a specialized tool designed to lift and hold cabinets in place while they are being attached to the wall. This can be particularly helpful when installing heavy upper cabinets.

Having all of these tools on hand before starting the cabinet installation process will ensure a smoother, more efficient, and ultimately more successful project. Taking the time to gather the necessary equipment will pay off in the form of professional-looking results and a kitchen that is both functional and aesthetically pleasing.

How To Install Upper Cabinets Like A Pro Cabinetselect Com

Cabinet Installation Kitchen Rta Cabinets Orange County Pre Made Whole Quartz Countertop Slab Prefab Granite

How To Install Cabinet Hardware With Young House Love

Must Have Tools For Cabinet Making And Furniture Building

20 Essential Cabinet Installation Tools That Make The Job Easy Electronicshub

How To Install Kitchen Cabinets Diy Family Handyman

Might Not Be Easy To Get The Hang Of Installing Cabinets

14 Must Have Cabinetmaking Tools York Saw And Knife

How To Install Kitchen Cabinets Young House Love

Must Have Tools To Install Cabinets The Handyman

Related Posts