What Tools Do I Need to Install Kitchen Cabinets?

Installing kitchen cabinets is a multifaceted project that necessitates precision, accuracy, and the proper tools. Attempting this task without the appropriate equipment can lead to frustration, substandard results, and potential damage to the cabinets or surrounding structures. This article provides a comprehensive overview of the essential tools required for a successful kitchen cabinet installation, categorizing them by function and offering insights into their importance.

Measuring and Leveling Tools

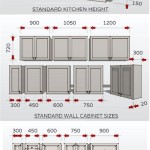

Accurate measurements are fundamental to any successful cabinet installation. A mistake at the measurement stage can propagate throughout the entire project, leading to misaligned cabinets and functional issues. Leveling is equally crucial; cabinets must be perfectly level and plumb to ensure proper door function and overall aesthetic appeal.

Tape Measure: A high-quality tape measure, preferably one that is at least 25 feet long, is indispensable. Look for a tape measure with a wide blade for increased rigidity when extending it over longer distances. The ability to accurately measure distances and transfer those measurements to the walls and cabinets is paramount.

Laser Level: A laser level projects a perfectly horizontal or vertical line, facilitating the accurate alignment of cabinets. While a traditional bubble level can be used, a laser level significantly speeds up the process and improves accuracy, especially when installing multiple cabinets. Models that project both horizontal and vertical lines simultaneously are particularly useful.

Bubble Level: In addition to a laser level, a traditional bubble level is still necessary. A 4-foot level is ideal for checking the overall level of the walls and the top edges of the base cabinets. A smaller level, such as a 2-foot level, is useful for checking individual cabinet faces and ensuring they are plumb.

Stud Finder: Locating wall studs is crucial for securely attaching cabinets to the wall. Stud finders use either electronic sensors or magnets to detect the location of studs behind drywall. An electronic stud finder is generally more accurate and can typically detect both wood and metal studs. A magnetic stud finder can be useful for locating nails or screws in the studs, providing a more direct indication of their position.

Measuring Square: A speed square or combination square is helpful for marking precise 90-degree angles. This is particularly useful when marking cut lines on cabinet components or when ensuring that cabinet faces are square.

Cutting and Drilling Tools

Cutting and drilling are essential aspects of cabinet installation, involving tasks such as trimming cabinet components, creating pilot holes for screws, and drilling holes for plumbing or electrical access. Proper selection and use of these tools are critical for achieving clean, accurate cuts and minimizing the risk of damage.

Circular Saw: A circular saw is used for making straight cuts in larger pieces of wood, such as cabinet fillers or panels. Opt for a saw with a sharp blade designed for cutting plywood or melamine, which are common cabinet materials. Using a guide, such as a straight edge clamped to the material, ensures accurate and straight cuts.

Jigsaw: A jigsaw is ideal for making curved or irregular cuts. It is commonly used for cutting out sink openings in countertops or for trimming cabinet components around pipes or other obstructions. Select a blade appropriate for the material being cut, and use a steady hand to follow the cut line.

Power Drill/Driver: A cordless power drill/driver is indispensable for driving screws and drilling pilot holes. Choose a model with variable speed and adjustable clutch settings to prevent over-tightening screws. Having multiple drill bits, including both standard twist drill bits and countersink bits, is essential.

Drill Bit Set: A comprehensive drill bit set, containing a variety of sizes, is necessary. Include twist drill bits for drilling pilot holes, spade bits or hole saws for drilling larger holes for plumbing or electrical access, and countersink bits for creating a recess for screw heads.

Multi-Tool: A multi-tool with various blades is useful for a range of tasks, including trimming door casings, cutting through drywall, and making small, precise cuts. It is particularly helpful for fitting cabinets tightly against walls or other surfaces.

Fastening and Assembly Tools

Securing cabinets to the wall and assembling cabinet components require specialized tools designed for driving fasteners and ensuring proper alignment. Using the correct tools for these tasks will ensure that the cabinets are securely mounted and aesthetically pleasing.

Impact Driver: While a drill/driver can be used for driving screws, an impact driver provides more torque and is better suited for driving long screws into studs. It is particularly useful for attaching cabinets to the wall, ensuring a secure and stable installation.

Screws: A variety of screws are needed, including cabinet installation screws (typically 2.5 to 3 inches long), wood screws for assembling cabinet components, and drywall screws for attaching temporary supports. Choose screws with flat heads for a flush finish. Select screws appropriate for the material being used, such as wood or metal studs.

Clamps: Clamps are essential for holding cabinet components together while the adhesive dries or while screws are being driven. Bar clamps are useful for clamping larger surfaces, while pipe clamps can be used for longer pieces. Spring clamps can be used for smaller tasks.

Cabinet Shims: Shims are thin pieces of wood or plastic used to level cabinets and fill gaps between cabinets and walls. Use a variety of thicknesses to achieve precise leveling. Plastic shims are preferable to wood shims because they are less likely to compress or rot.

Caulk Gun and Caulk: Caulk is used to seal gaps between cabinets and walls, countertops, or other surfaces. Choose a caulk that is paintable and appropriate for use in kitchens, such as a silicone or acrylic latex caulk. A caulk gun is necessary for applying the caulk smoothly and evenly.

Safety Equipment

Safety is paramount when working with power tools and construction materials. Wearing appropriate safety equipment protects against potential injuries and ensures a safe working environment.

Safety Glasses: Safety glasses are essential for protecting the eyes from flying debris when cutting, drilling, or sanding. Choose glasses that fit comfortably and provide adequate coverage.

Hearing Protection: Power tools can generate significant noise levels, which can damage hearing over time. Wear earplugs or earmuffs to protect your hearing.

Dust Mask or Respirator: Cutting and sanding cabinet materials can generate dust, which can irritate the lungs. Wear a dust mask or respirator to protect your respiratory system. A respirator is recommended for prolonged exposure or when working with materials that produce hazardous dust, such as MDF.

Work Gloves: Work gloves protect your hands from cuts, splinters, and abrasions. Choose gloves that fit well and provide a good grip.

Additional Tools and Supplies

While the tools listed above are essential, several additional tools and supplies can make the installation process easier and more efficient.

Utility Knife: A utility knife is useful for a variety of tasks, including scoring drywall, cutting caulk, and trimming shims. Choose a knife with a retractable blade and a comfortable grip.

Pencil: A pencil is essential for marking measurements and cut lines. Keep a sharp pencil handy at all times.

Putty Knife: A putty knife is used for applying and smoothing wood filler or patching compounds.

Sanding Block or Sandpaper: Sanding is necessary to smooth rough edges or surfaces. Use a sanding block or sandpaper with varying grits.

Crowbar or Pry Bar: A crowbar or pry bar can be useful for removing old cabinets or trim.

Painter's Tape: Painter's tape can be used to protect surfaces from scratches or paint splatters.

Shop Vacuum: A shop vacuum is essential for cleaning up dust and debris. Keep the work area clean to improve visibility and prevent accidents.

Touch-Up Paint or Stain: Touch-up paint or stain can be used to conceal minor scratches or blemishes on the cabinets.

Cabinet Installation Jig: Some specialized jigs can aid in cabinet installation, such as jigs for installing drawer slides or door hinges. These jigs can improve accuracy and speed up the installation process.

Having the right tools is only part of the equation; understanding how to use them safely and effectively is equally important. Before beginning the installation, familiarize yourself with the operation of each tool and practice using them on scrap materials. Taking the time to gather the necessary tools and learn how to use them will ultimately result in a more professional and satisfying cabinet installation.

Preparing the Installation Area

Prior to commencing the cabinet installation itself, preparing the space where the cabinets will reside is paramount. This preparatory phase lays the groundwork for a smoother, more accurate, and ultimately more successful installation. Addressing potential issues and ensuring a clean, level workspace are critical for optimal results.

Wall Inspection and Repair: Begin by thoroughly inspecting the walls where the cabinets will be mounted. Look for any signs of damage, such as cracks, holes, or uneven surfaces. Repair any damage with patching compound and sand smooth. Uneven walls can cause cabinets to be out of plumb, leading to functional and aesthetic problems.

Stud Location and Marking: Use a stud finder to accurately locate and mark the position of wall studs. The cabinets must be securely fastened to the studs to support their weight and prevent them from pulling away from the wall. Mark the stud locations clearly, using a pencil or painter's tape. Double-check the stud spacing to ensure that it aligns with the cabinet mounting points.

Floor Leveling: Check the level of the floor where the base cabinets will be installed. Uneven floors can cause cabinets to be out of level, resulting in misaligned doors and drawers. Use shims to level the floor as needed. A self-leveling compound can also be used to address more significant floor irregularities.

Removal of Obstructions: Remove any obstructions that could interfere with the cabinet installation, such as old cabinets, appliances, or trim. Disconnect any plumbing or electrical connections before removing old cabinets. Ensure that the area is clear and free of debris.

Protection of Surrounding Surfaces: Protect surrounding surfaces, such as floors and countertops, from scratches or damage during the installation process. Cover these surfaces with drop cloths or protective sheeting. Use painter's tape to protect walls or trim that will not be removed.

By meticulously preparing the installation area, potential problems can be identified and addressed before they impact the cabinet installation. This proactive approach saves time and effort in the long run, ensuring a more efficient and professional outcome.

Cabinet Installation Kitchen Rta Cabinets Orange County Pre Made Whole Quartz Countertop Slab Prefab Granite

How To Install Upper Cabinets Like A Pro Cabinetselect Com

How To Install Cabinet Hardware With Young House Love

11 Must Have Cabinetmaking Tools Wood

How To Install Kitchen Cabinets Diy Family Handyman

20 Essential Cabinet Installation Tools That Make The Job Easy Electronicshub

Must Have Tools For Cabinet Making And Furniture Building

Must Have Tools For Cabinet Making And Furniture Building

Might Not Be Easy To Get The Hang Of Installing Cabinets

How To Install Kitchen Cabinets Young House Love

Related Posts