Wood Veneer For Kitchen Cabinets: A Comprehensive Overview

Wood veneer, a thin slice of wood adhered to a substrate material, presents a compelling alternative to solid wood for kitchen cabinets. This application balances the aesthetic appeal of natural wood with considerations of cost, stability, and environmental impact. Understanding the properties, types, and proper usage of wood veneer is crucial for making informed decisions regarding kitchen cabinet design and construction.

The core concept behind wood veneer lies in maximizing the efficient use of valuable timber. Instead of constructing entire cabinets from solid wood, a thin layer of high-quality wood is applied to a structurally sound core material, such as plywood, particleboard, or MDF (Medium Density Fiberboard). This method allows for the creation of cabinets that mimic the appearance of solid wood at a reduced cost and with improved dimensional stability.

The process of creating wood veneer involves slicing thin layers of wood from a log using various methods, including slicing, rotary cutting, and half-round slicing. Each method produces a distinct grain pattern, influencing the final appearance of the veneer. These veneers are then meticulously applied to the chosen substrate using adhesives and specialized machinery, ensuring a strong and durable bond.

Advantages of Using Wood Veneer for Kitchen Cabinets

Several key advantages contribute to the popularity of wood veneer for kitchen cabinets. These benefits encompass cost-effectiveness, environmental considerations, and enhanced design possibilities.

Firstly, wood veneer offers a significant cost advantage compared to solid wood. The amount of real wood required is dramatically reduced, lowering the material cost. This allows homeowners to achieve the desired look of solid wood kitchens without incurring the high expense associated with solid wood construction. The price difference can be substantial, particularly when using exotic or rare wood species.

Secondly, wood veneer promotes sustainable forestry practices. By utilizing a thin layer of wood over a substrate, a single tree can yield a significantly larger surface area of usable material compared to solid wood construction. This reduces the demand for timber and helps conserve forest resources. Furthermore, the use of engineered wood products like MDF for the core can incorporate recycled wood fibers, further enhancing the environmental benefits.

Thirdly, wood veneer offers superior dimensional stability compared to solid wood. Solid wood is prone to warping, cracking, and expansion/contraction due to changes in humidity and temperature. These issues can compromise the structural integrity and aesthetic appeal of kitchen cabinets. Wood veneer, when properly applied to a stable substrate, minimizes these risks. The substrate provides a rigid and stable base, preventing the veneer from warping or cracking due to environmental fluctuations. This is especially crucial in kitchens, where humidity levels can fluctuate significantly.

Fourthly, wood veneer provides a greater consistency in appearance compared to solid wood. Solid wood can exhibit variations in grain pattern, color, and knots, which can be difficult to control in a large-scale project like a kitchen. Wood veneer allows for a more uniform and consistent appearance across all cabinet doors and panels. Manufacturers can carefully select and match veneer sheets to ensure a cohesive and aesthetically pleasing design.

Types of Wood Veneer and Their Characteristics

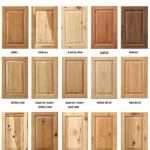

Various types of wood veneer exist, each characterized by its cutting method and the resulting grain pattern. Understanding these differences is essential for selecting the appropriate veneer for a specific kitchen design.

Plain Sliced Veneer: This is the most common type of veneer. It is produced by slicing the log parallel to the center, creating a cathedral grain pattern. This pattern is characterized by pointed arches or “cathedrals” that run vertically along the veneer surface. Plain sliced veneer is relatively cost-effective and provides a classic, traditional look.

Quarter Sliced Veneer: This veneer is produced by slicing the log at a 90-degree angle to the growth rings. This results in a straighter, more uniform grain pattern compared to plain sliced veneer. Quarter sliced veneer is less prone to warping and twisting and is often used in high-end applications where stability and a refined aesthetic are desired.

Rotary Cut Veneer: This method involves mounting the log on a lathe and rotating it against a knife, peeling off a continuous sheet of veneer. Rotary cut veneer produces a wide, bold grain pattern that is often referred to as a "wild" or "busy" grain. It is a cost-effective method for producing large quantities of veneer, but the resulting grain pattern may not be suitable for all kitchen designs.

Rift Cut Veneer: This veneer is similar to quarter sliced veneer but is cut at a slightly different angle to minimize the appearance of medullary rays, which are radial cells that appear as flecks or lines in some wood species. Rift cut veneer produces a very consistent and linear grain pattern, making it a popular choice for contemporary and minimalist kitchen designs.

In addition to the cutting method, the species of wood used to create the veneer plays a crucial role in the final appearance and performance of the cabinets. Common wood species used for veneer include oak, maple, cherry, walnut, and birch. Each species has its own unique color, grain pattern, and hardness characteristics. Exotic wood species, such as zebrawood, wenge, and ebony, are also available for creating high-end, custom kitchen designs.

Considerations for Installing and Maintaining Wood Veneer Kitchen Cabinets

Proper installation and maintenance are essential for ensuring the longevity and beauty of wood veneer kitchen cabinets. Neglecting these aspects can lead to premature wear and tear, delamination, and other issues.

Installation should be performed by experienced professionals who are familiar with working with wood veneer. The substrate must be properly prepared before the veneer is applied. This includes ensuring that the surface is clean, smooth, and free of any defects. The adhesive used to bond the veneer to the substrate must be appropriate for the materials being used and applied according to the manufacturer's instructions. Proper clamping and pressure are essential to ensure a strong and durable bond.

Environmental control is paramount. Maintaining consistent humidity and temperature levels in the kitchen is crucial to prevent warping, cracking, and delamination of the veneer. Avoid exposing the cabinets to excessive moisture or direct sunlight. Use exhaust fans when cooking and showering to reduce humidity. Consider using a dehumidifier in areas with high humidity levels.

Regular cleaning and maintenance are essential for preserving the appearance of wood veneer kitchen cabinets. Use a soft, damp cloth to wipe down the cabinets regularly. Avoid using harsh chemicals or abrasive cleaners, as these can damage the veneer finish. For stubborn stains, use a mild soap and water solution. Always dry the cabinets thoroughly after cleaning.

Avoid using furniture polish or wax on wood veneer kitchen cabinets. These products can build up over time and create a hazy or greasy film. If you want to enhance the shine of the cabinets, consider using a specialized wood cleaner and restorer that is designed for wood veneer surfaces. Follow the manufacturer's instructions carefully.

Protect the cabinets from scratches and dents. Use placemats and coasters to protect countertops from spills and heat. Avoid sliding heavy objects across the cabinet surfaces. If scratches or dents do occur, they can often be repaired by a professional wood restorer.

Repairing damage promptly is important. If the veneer becomes chipped or delaminated, it should be repaired as soon as possible to prevent further damage. Small chips can often be repaired with wood filler or touch-up paint. Larger areas of delamination may require professional repair or replacement of the veneer.

Consider the long-term cost of maintenance when choosing between different types of wood veneer. Some veneers are more durable and resistant to wear and tear than others. If you are concerned about maintenance costs, choose a veneer that is known for its durability and ease of cleaning.

In summary, wood veneer offers a compelling combination of aesthetic appeal, cost-effectiveness, and environmental benefits for kitchen cabinets. Understanding the different types of veneer, proper installation techniques, and essential maintenance practices is key to achieving a beautiful and durable kitchen that will last for years to come.

Refinishing Kitchen Cabinets Modern Refacing Made Easy Wisewood

Wood Veneer Vs Melamine Comparing Kitchen Cabinet Materials

Kitchen Cabinets What Is A Wood Veneer Kitchens

Wood Veneers Vs Solid Which One S Better For Kitchen Cabinets Ikonni

7 个wood Veneer Kitchen Cabinets 点子

Customized Modern Flat Timber Wood Veneer Kitchen Cabinet China Marble Granite Units Venner Cabinets Made In Com

Using Timber Veneer In Your Luxury Kitchen Dan Kitchens

Top Kitchen Design Trends Of 2024 You Can Manifest Using Engineered Veneer Blog Decowood Veneers

Diy Cabinet Refacing Budget Friendly Made Easy Wisewood

Veneer Kitchen Cabinets Pros And Cons Pa

Related Posts